Orifice Meter Structure and Working

Orifice Meter Structure and Working:- Orifice Meter is an instrument which is used to measure average velocity of a flowing fluid or flow rate of a flowing fluid.

It measures the average velocity and the flow rate of the flowing fluid by introducing a restriction in the direction of the flowing fluid. The effect of the restriction is to lower the pressure drop of the flowing fluid. This decrease in pressure can be related to average velocity or the flow rate of the flowing fluid mathematically.

This restriction is called an Orifice Plate.

Structure of an Orifice Plate

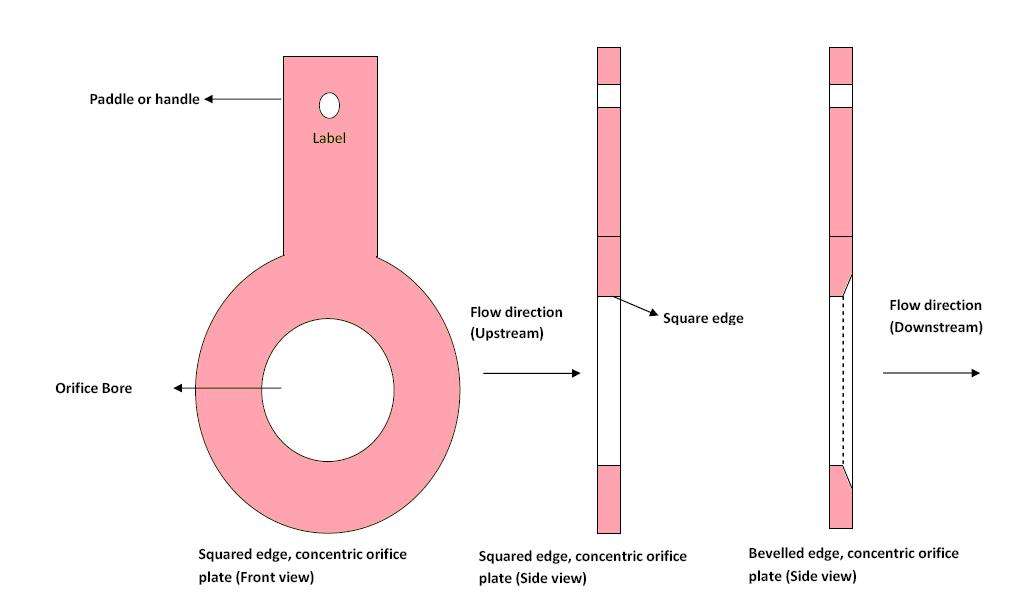

The thickness of the plate, the location of the hole on the plate, the size of the bore, the number of bores on the plate; variations in these constraints gives rise to a variety of different types and designs of orifice plates. An example of orifice plate is shown

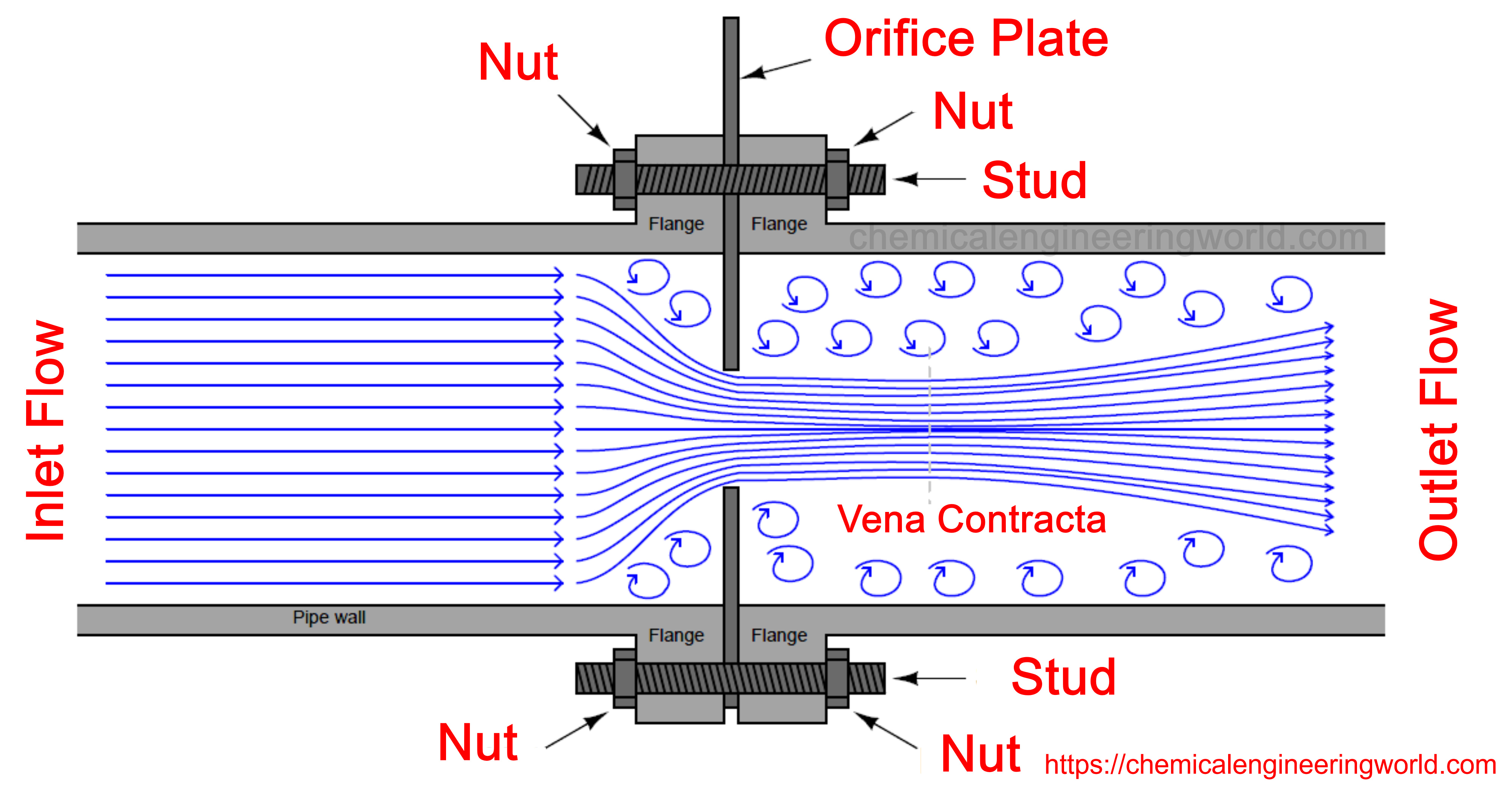

The orifice plates are placed in between the flanges of the two sections of pipe and they are tightened by a nut.

The main purpose of an orifice plate is to act as a restriction in the direction of flow of fluid in order to decrease the pressure of the flowing fluid but it must be properly designed so that it doesn’t lower pressure too much and also it most not create much turbulence on the downstream side of the plate.

In order to achieve this to a great extent the diameter of the hole is not constant throughout the thickness of the plate. The structure of the hole is such that it is tapered with increasing size in the direction of the flowing fluid. The tapered bore is shown in Figure

The common type of orifice plate has a bore at its center but many applications which contains particulate solids in the flowing fluid or slurry use an eccentric type of orifice meter. The bore in an eccentric type of orifice meter is placed off center. For the applications with systems working with slurry the bore in the orifice plate is placed at the bottom of the plate. In this way the accumulation of solids in the pipe is eliminated.

Working of Orifice Meter

The fluid flowing in the pipe converges when it starts nearing the plate. The degree of convergence depends on the size and location of bore. After the fluid reaches the bore and passes through the bore, its convergence does not stop immediately. As the fluid is converged more and more, its pressure decreases more and more.

Due to the inertia of flowing fluid, the liquid converges until some distance downstream the plate and it reaches a point known as vena contracta. The state of the fluid at the point of vena contracta is such that it is the point of maximum velocity and minimum pressure.

The orifice plates have to be properly designed so that the pressure of the liquid does not fall below its vapour pressure at the fluid temperature because if it falls below the vapour pressure then the liquid will vaporize in the vena contracta region and it may happen that the vapours will collapse in some region downstream to vena contracta, this is the phenomenon of cavitation and it damages the pipe.

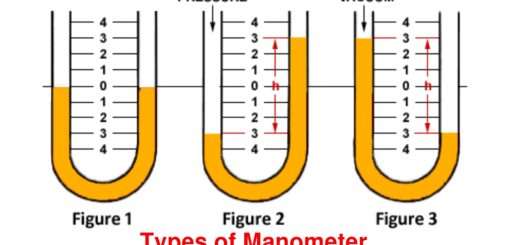

The decrease in pressure is sensed by a manometer or a pressure gauge