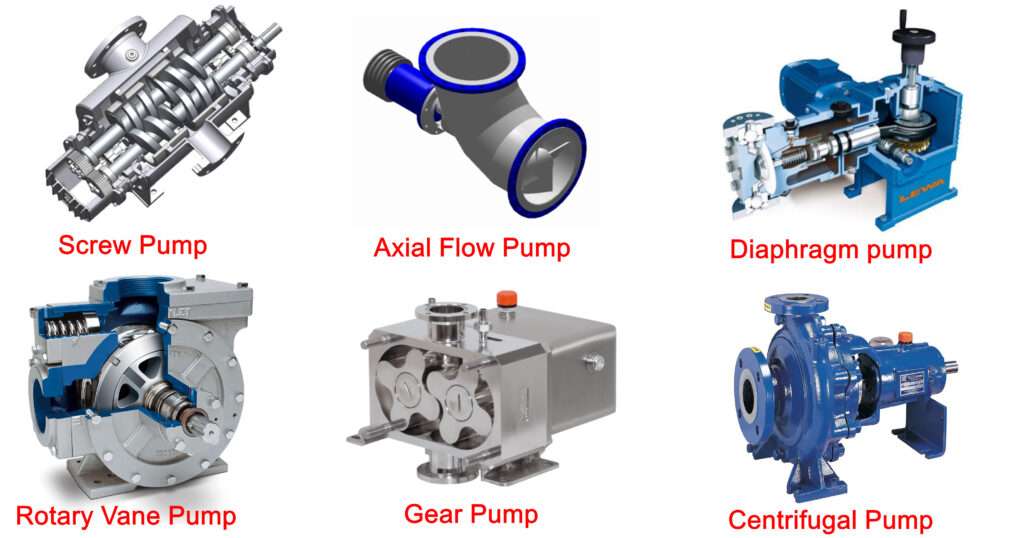

Types of Pumps and Applications

Types of Pumps and Applications:- A Pump is a mechanical device which is used to move liquids or slurries from one point to another point by increasing the mechanical energy of the liquid or the slurry. Since energy is supplied to the pump in order for it to work, they are called energy absorbing devices. They add energy to the fluid and in the process they pressurize the fluid.

The Pumps are classified into two classes; positive displacement pumps and dynamic pumps. In positive displacement pumps the fluid is directed into closed volume and the boundaries of the closed volume move in such a way that they expand or contract in order to receive and discharge the liquid. In dynamic pumps, there is no closed volume but there are rotating blades called impeller blades which input energy in the fluid

1. Positive Displacement Pumps

Positive Displacement pumps are mostly divided into two classes; Rotary and Reciprocating positive displacement pumps.

A. Rotary Positive Displacement Pumps

The defining feature of these pumps is that they have a rotating mechanism; this rotating mechanism creates a vacuum and it drives the fluid inside the pump. It can handle highly viscous liquids quite efficiently. Some of the rotary type positive displacement pumps are Rotary vane pumps, Screw pumps and Gear pumps.

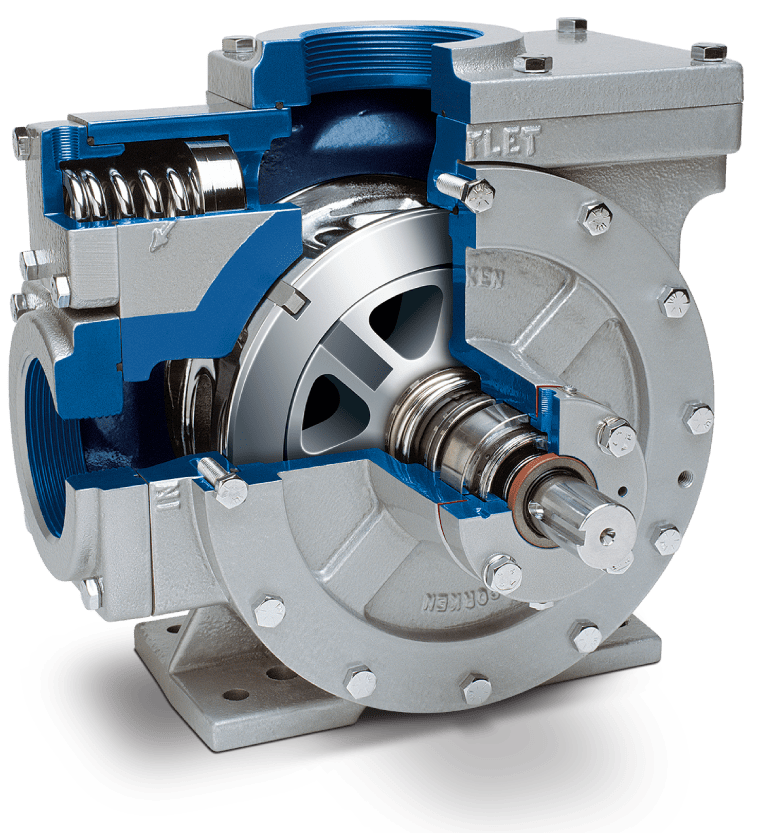

Rotary Vane Pumps

These pumps consist of vanes mounted on the rotor. The rotor is placed inside a cavity where it rotates in order to draw in liquid. These vanes can have variable length and the vanes may be installed in such a way that they touch the walls of the pump casing

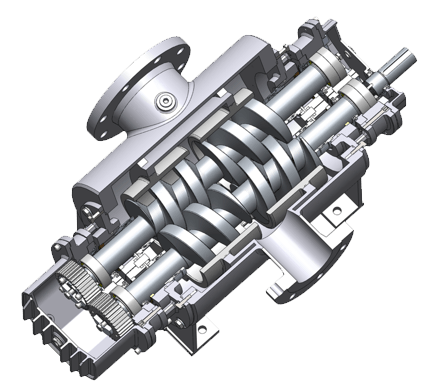

Screw Pumps

These pumps use screws to move the liquid. A single screw can be used which rotates and the liquid moves axially along the screws. Double screws can also be used where, if one screw rotates clockwise then the other rotates counter clockwise. The advantage in using such pumps to drive viscous liquids is that foam formation does not take place.

Gear Pumps

It consists of two gears. The gears have very tight clearance, it means the gap between the gear and the pump casing is in micrometers. This tight clearance prevents back flow of water. When the gear rotates, a vacuum is created at the input of the pump which drives the liquid inside the pump.

B. Reciprocating Positive Displacement Pumps

The defining feature of reciprocating pumps is that they have an oscillating component which causes the liquids to move through the pumps. The oscillating components can be of the type piston, plunger or diaphragm. The pumps corresponding to the components are called Piston pump, Plunger pump and Diaphragm pump.

Piston Pump and Plunger Pump

In the plunger pump, we have a plunger which slides up and down in order to move the liquid. The high pressure seal is stationary.

In the piston pump, the piston is responsible for driving the liquid, The high pressure seal reciprocates with the piston.

Diaphragm pump

The Diaphragm pump contains oscillating pair of membranes. Either side of the diaphragm contains check valves. When the diaphragm moves at one side the pressure decreases at other and it draws in liquid.

2. Dynamic Pumps

Dynamic pumps are the types of pumps which increase the velocity of the liquid as the liquid is driven inside the pump but as pump reaches the outlet this increased kinetic energy converts to potential energy. In this case it means increased pressure. Types of dynamic pumps are centrifugal pump, axial flow pump and mixed flow pump.

A. Centrifugal Pump

Centrifugal pumps consist of an impeller which rotates with the help of a shaft connected to a motor. The liquid enters the pump axially through the eye of the casing. The impeller throws the liquid onto the circumference of the casing due to which the liquid enters the diffuser section where the deceleration of the liquid and increase in pressure of liquid takes place.

B. Axial Flow Pump

An Axial flow pump is a pump which contains propeller. A propeller is an axial flow impeller. The fluid enters and moves inside the pump and also exits the pump along the shaft of the propeller.

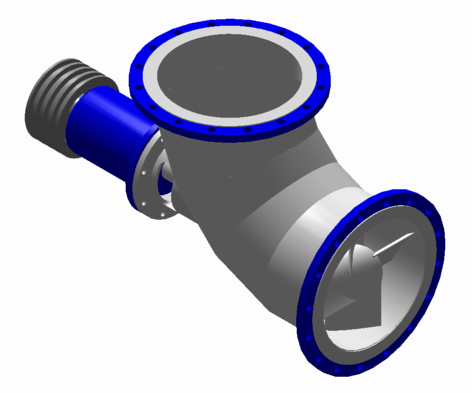

A. Mixed Flow Pump

They are a type of pump in which the fluid moves along the radius as well as the axis of the impeller. The impeller turns diagonally inside the pipe. Mixed flow pump has characteristics of centrifugal pumps and axial flow pumps.