Control Valves Interview Questions

Control Valves Interview Questions:- in this post 27 nos. Questions discussed which is frequently asked in Interview

1. What is the valve cone?

The valve cone may be a movable component inside the valve that bears on the valve seat. By means that of the cone stroke the valve is opened, throttled or closed.

2. What is the valve seat?

The valve seat is that the apron for an outlined flow through opening within the valve through that the medium to be regulated needs to flow.

3. How to define seat leak class for control valves?

A control valve’s ability to shut off must do with several factors. Seat material, actuator thrust, pressure drop, and also the kind plug (balanced or unbalanced) will all play a section in however well a specific control valve shuts off. Seat leak Classifications There is literally six completely different seat leak classifications as outlined by IEC 60534-4 std or ANSI/FCI seventy.2.

They normally range from class IV to class Vl class IV is additionally referred to as metal to metal. it’s the type of leak rate you’ll expect from a valve with a metal plug and metal seat. Class Vl is understood as a soft seat classification.

Soft Seat Valves area unit those wherever either the plug or seat or each area unit made of some reasonably composition material like Teflon or similar.

4. What is the difference between flashing and cavitation?

Cavitation may be a condition that happens in liquid flow wherever the inner pressure of the liquid, at some Location falls below the vapour pressure and vapour bubbles formation takes place.

After this time the pressure rises higher than the vapour pressure once more and through this pressure recover stage (recall additionally the conception of FL) the bubbles collapse, and cavitation takes place.

Flashing may be a condition that happens with liquid flow wherever the pressure falls below the vapour pressure (same as cavitation) and remains below it. There are a unit then 2 phases flowing (i.e. liquid and vapour) downstream and no collapsing of bubbles takes place.

5. Why a control valve on refrigerant Service can not be mounted with actuator in horizontal position?

The working rule of the extended bonnet (named “cold box”) employed in refrigerant service (below -100°C) is predicated on the principle that portion of LNG that evaporates and stagnates within the higher portion of the bonnet contains a operate of thermal insulation between the process fluid and also the gland packing.

In this manner ice formation on valve stem is avoided. To grant this profit the stem/actuator axis should be in upright position. so valves put in on a vertical pipe (with the actuator in horizontal position) cannot work properly.

6. What is the distinction between “Rangeability” and “Turn-down” in an exceedingly steam DE-superheating system ?

The term “rangeability” commonly refers to a mechanical conception applied to one throttling device. F.i. for a control valve the “rangeability” is magnitude relation between the max flow (or Cv) and also the minimum governable flow (or Cv).

When 2 of such devices area unit associated, in our case on water and steam line, the minimum and most governable flow of the system as an entire can be tormented by different factors.

Typically in steam acquisition systems some prescriptions in terms of steam velocity area unit needed for a decent performance (not under..) and thus the operating range of the system is also under the “rangeability” of every individual device.

Therefore the magnitude relation between max. and minimum governable flow of the complete system is what we tend to decision “turn down”.

7. How will cavitation damage be contained?

Several ways exist for treating cavitation in control valves. The primary is to pick out valves with high values of fl (recovery factor) eliminating cavitation.

The second is to make sure that the plug and seat area unit product of a material which will resist the damage (e.g. stellite hard facing).

The third is to control wherever the bubbles collapse and keep this aloof from vulnerable elements (for instance on the brink of internal surface of valve body or pipe).

8. What is the pressure setting range?

The pressure setting range indicates the range at intervals that a valve may be set or used.

Example: The indication pressure vary 4-6 bar means that for a pressure reducing valve the outlet pressure may be set between four and six bar for an overflow valve (back pressure regulator) – the I/L pressure may be set between four and six bar for a hurt and emission valve the valve may be used for this system pressure range

9. What is the reduction ratio?

The reduction ratio indicates the maximum. ratio of I/L and outlet pressure which might be reduced among one step by a pressure reducing valve.

Example one : Reduction ratio 20:1 (the regulation data sheet of the valve indicates 20)

Example two : The face value for the outlet pressure 1.2 bar is that the highest permissible pv = 20 x one.2 bar = 24 bar

10. What is a control line?

The control line takes the I/L and outlet pressure to be regulated from the pipeline and transfers it to the control unit.

Not each pressure control valve needs a control line. The control line may also be accustomed set pressures at locations remote from the valve.

11. What is the distinction between a start-up and continuous bleeding valve?

The start-up bleeding valves bleed plants with low internal pressure throughout start-up or filling. The float acts directly onto the cone. Such valves have an oversized seat diameter to make sure quick bleeding at a pressure below 0.1 bar.

During operation they’re unbroken closed by the inner pressure of the vessel. just in case of a suddenly occurring vacuum the valves open and compensate the pressure. so damages caused by a vacuum are going to be avoided.

The continuous bleeding valves area unit accustomed evacuate the air accumulating throughout operation. they’re supplied with a lever transmission so they additionally operate at terribly low or terribly high pressures. If air intake is to be avoided the outlet is to be supplied with a non-return valve. In such a case they’re going to act as bleeding valves while not venting operate.

12. What is Nm³ (cubic metre standard), Sm³ (American kiloliter standard) and Bm³ (cubic metre throughout operation)?

Nm³ : Volume of a medium (liquid or gas) at the standard state one bar (abs) 20°U Sm³: -> engl: the american variant of Nm³

Bm³ : Volume of the medium (liquid or gas) within the operative mode. i.e. at operative pressure and operative temperature.

Attention: Bm³ and Nm³ could usually differ from one another owing to the compressibility of the medium. In such a case the differentiation between Bm³ and Nm³ is of specific importance.

13. What is the distinction between a pressure reducing valve and a pressure maintaining valve?

Both valves keep the chosen set pressure constant. The pressure reducing valve will thus on the downstream facet while the pressure maintaining valve will thus on the upstream facet of the valve (UV=backpressure regulator).

Which parameters area unit necessary for the choice of the nominal diameter except the Kv(s) values)?

The medium, flow rate, viscosity and also the pressure range to be regulated.

14. What will control unit mean?

The pressure to be regulated is transferred to the pressure control valve mechanism via the control unit.

The pressure functioning on the control surface closes (pressure reducing valve) or opens (backpressure regulator) the valve against the spring force.

Three construction varieties are distinguished:

1. diaphragm

2. piston with O-ring and different seals

3. bellow

15. Why is it better to increase the pipeline in some cases?

In several cases the valve is sufficiently dimensioned for an exact application with regards to the Kv(s) value, however it would be too little in respect of nominal diameter and also the resulting flow velocities.

Too high flow velocities lead to noise, pressure rise and wear and tear.

On alittle scale the flow velocity may be reduced to a permissible value because of the extended pipeline. The pipeline extension is to be disbursed by the client.

16. What is the distinction between safety valve and back pressure regulator?

The safety valve is to securely discharge the medium at a planned nominal value throughout an exact pressure relief process.

The overflow valve (backpressure regulator) limits the pressure upstream of the valve to the set (but alterable) face value.

The backpressure regulator solely discharges the amount of the medium required to achieve the face value.

17. Why may be a control line needed?

Some valve designs need control lines to securely transmit the desired set pressure to the control unit.

Control lines will enhance the control properties and area unit accustomed notice special applications (e.g. regulation of differential pressure, of quantities, or vacuums).

18. What is the control deviation & its types should it be?

In the range from ten % to seventy % of the possible rate of flow the pressure variation and also the set value (psoll) should not vary over + five %. The control deviation indicates the extent of the variation.

19. Why will a leakage line be necessary?

In case of poisonous or dangerous media the valve should be supplied with a closed spring cap (with adjusting screw seal) with leak line connection.

During the on-site assembly a leakage line needs to be arranged that drains the medium safely just in case the control unit becomes defective.

20. What is the differential pressure, Δp?

The differential pressure defines the pressure distinction between I/L pressure and outlet pressure. If pressure ranges area unit given, the littlest pressure distinction has relevancy with regards to valve design..

21. What is a released valve?

On a released valve the forces working on the cone area unit compensated on an equally sized release surface because of the I/L and outlet pressure. so the valve features significantly higher control properties.

22. What will exhausting facing mean?

It is suggested that the cone for pressure control valves for liquids and with a pressure drop of abt. > twenty five bar be designed with a tough facing layer. This may prevent early wear and tear because of cavitation.

23. Why is that the flow velocity thus important?

In pipelines bound flow velocities area unit allowable depending on the medium. additionally to the KV(s) value the flow velocity may be a decisive value for valve orienting .

24. What is an outlet pressure pH (p2)?

The outlet pressure indicates the pressure within the system downstream of the valve.

25. What is a pressure drop?

The pressure drop indicates the active pressure distinction between the effective I/L and outlet pressure.

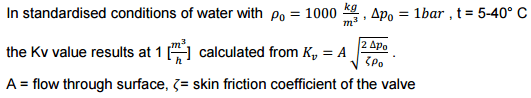

26. What will kV value mean?

The kV price may be a reference value for the rate of flow of valves:

27. What will Kvs value mean?

For engineering a necessary kV value is calculated on basis of the given operative conditions. normally AN allowance of half-hour is additional. The kV value of the valve ought to reach this Kvs value.

What is an I/L pressure pv (p1)?

The I/L pressure indicates the pressure within the system upstream of the valve.

Image:- flowserve.com