CIRCULATING FLUIDIZED BED REACTOR

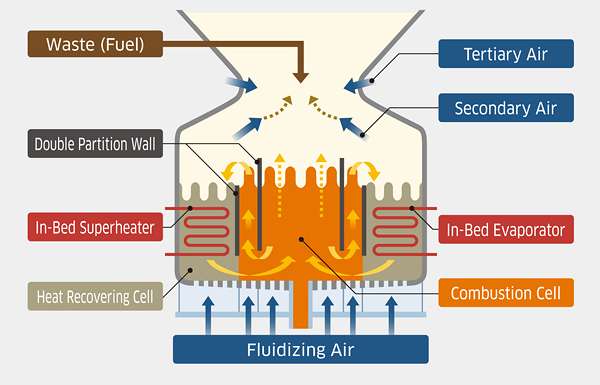

A circulating fluidized-bed (CFB) reactor is extremely the same as a bubbling fluidized-bed

reactor. the main distinction is that the gas rate. If the gas rate of a bubbling

fluidized bed will increase, at some Location the force exerted on the particle are enough

to move it upwards, carrying it outside of the bed. this case is named elutriation.

In a CFB, elutriation carries each sand and char particles outside of the bed. Once

char and sand area unit separated from the most gas stream within the cyclone, the char is combusted

to provide extra energy for the sand. The warm sand is then recirculated back to the reactor. during this kind of reactor, the sand is that the heat carrier, and it provides a large fraction of the warmth needed to keep up the reactor temperature.

For this reason, heating needs for CFB area unit considerably below those of bubbling

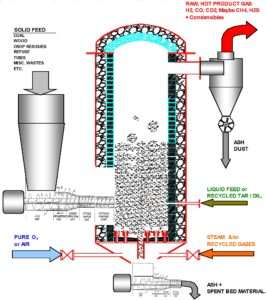

fluidized beds. A schematic of a CFB is shown in Figure below

In oil refineries, fluid catalytic cracking (FCC) units truly use this principle to

avoid catalyst deactivation. the aim of fcc is to convert the low-value, heaviest

portion of the oil into lighter and more valuable product like hydrocarbon and diesel. As

the name implies, fcc is predicated on maintaining the solid catalyst (a zeolite) in an exceedingly fluidized

state. In alternative words, the bed material is additionally the catalyst. throughout the method, coke

is formed on the catalyst surface. Coke and char area unit similar materials: each area unit solid

carbonaceous materials that result from thermochemical processes. The term “coke”

is a lot of normally utilized in catalytic processes, though. once coke formation within the

FCC reactor, the catalyst is distributed to a re generator,where the coke is burned off to produce

the process energy. The regenerated catalyst is then recycled back to the fluidized bed.

As with bubbling fluidized beds, CFBs relish sensible temperature management and uniformity

of conditions, also as simple scale-up. The integrated system provides the way

to save energy, however the system is additionally a lot of complicated and needs careful management in

order to function properly.

Because of the management needs, CFBs area unit generally solely utilized in industrial

application. Lab-scale fluidized beds area unit nearly always of the bubbling kind.