Plastic to Fuel | Pyrolysis Process

Plastic to Fuel | Pyrolysis Process

Plastic to Fuel | Pyrolysis Process

Plastics are mouldable polymers which can deform to a very high degree. They are a range of organic compounds which are mostly synthetic, derived from petrochemicals. Some plastics are also semi-synthetic in nature and can be made from renewable materials.

Plastics have found wide varieties of use in wide varieties of industries. They are most used in applications of piping, plumbing and vinyl siding. They are also used in automobiles, furniture and toy industries. Medical equipments have found a lot of uses for plastics.

Due to increase in human population, rapid economic growth and continuous urbanization; the use and production of plastics is also increasing very rapidly. Since plastics have a short lifespan of use, this also means that the plastic wastes are also increasing rapidly. Most of the plastics are non-biodegradable hence if they are dumped into the soil then they are going to stay in that area for hundreds of years and will render that piece of land useless for growing crops and even for the sake of urbanization.

If plastics are dumped in the seas then they will float and follow the currents. It has led to accumulation of plastics in various areas of oceans. The accumulation is even as large as size of islands. This poses a threat to the sea life.

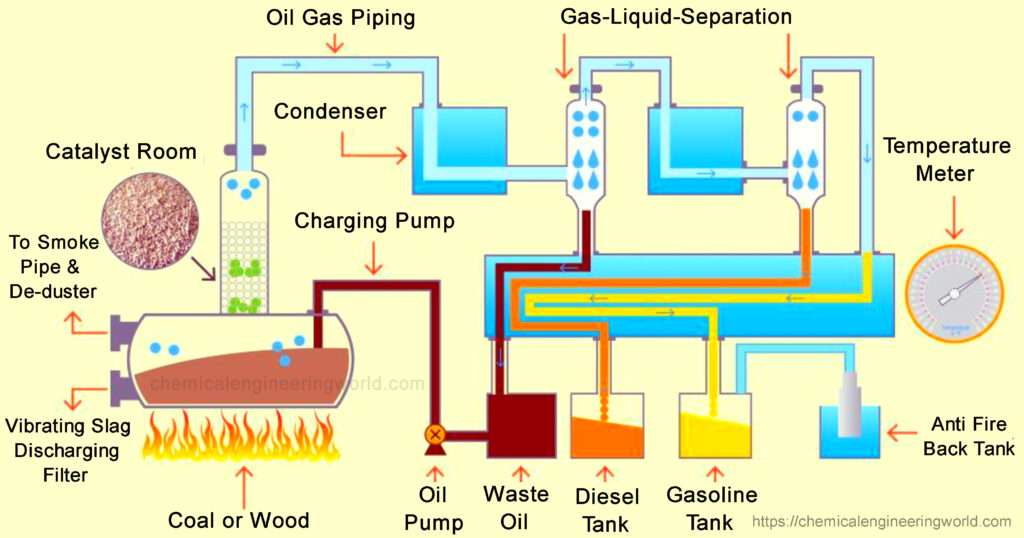

Disposal of plastic wastes is a big problem hence it has been recommended time and time again to recycle the plastic materials. Pyrolysis is one way to recycle the plastic material. The basis is that pyrolysis of plastic can be done to produce oil. This oil is then used as a fuel. The method of pyrolysis involves thermal degradation of plastic at different temperatures in the absence of oxygen.

Plastic waste raw material is first obtained and then it is pretreated in order to remain any material which is foreign to the process of conversion of plastic to fuel. In short, impurities are removed from the raw material.

Then the pre-treated raw material is grinded to the required size as desired before inputting the grinded raw material in the reactor, the pyrolysis chamber. The size should be proper so that the reaction is able to occur smoothly and efficiently.

The pyrolysis chamber is loaded with the grinded plastic along with a suitable catalyst in order to promote specific types of chemical reactions. The temperature of the reaction can range from 200-900C based on the quality of the liquid oil desired further down the line as a product. The grinded raw material first gets melted and then it gets vaporized.

The vapors are then passed to condensers in series in order to condense it into a liquid. This liquid is the oil but it is further sent for the process of refining. This refined liquid is the desired oil which is used as a fuel. They are also put into category of biofuels depending on the type of raw material selected. The oil is multipurpose in nature and can also be used in cars.

Image/Reference:- frontiersin, ecoideaz