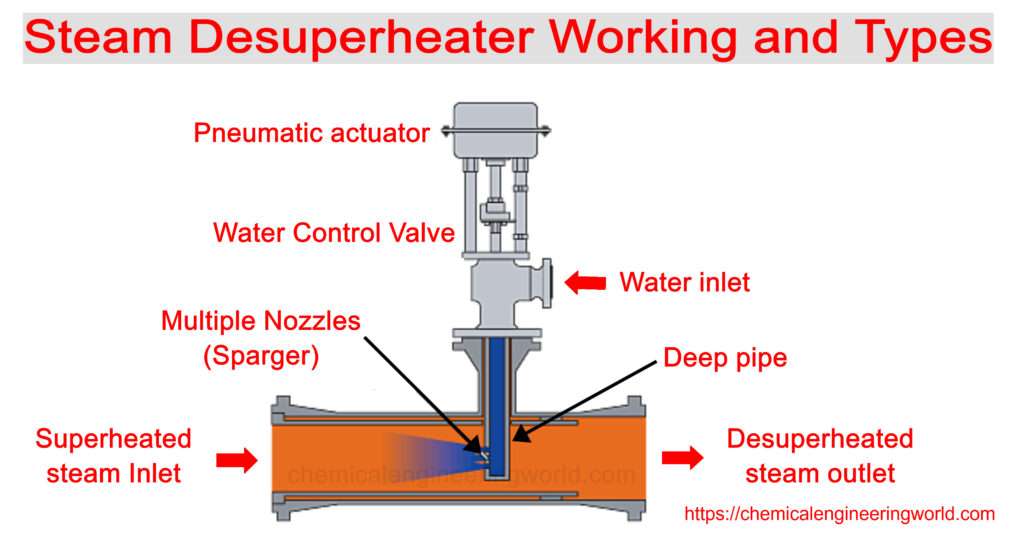

Steam Desuperheater Working and Types

Steam Desuperheater Working and Types:- In certain process industries and especially in high heat generation plants, superheated steam results in the process. Superheated steam is the steam whose temperature is higher than the temperature which will correspond to the saturation pressure of the steam. In the superheated steam, the vapor and the condensing liquid are not in equilibrium with each other.

Although superheated steam has more energy than saturated steam but it also has the same heat content as that of the air, this makes it act like an insulator during transfer of heat. Hence, superheated steam is used during power generation process and the saturated steam is used during heat transfer operations. If a process requires both power generation and heating then the superheated steam is first utilized in power generation and then for the heating purposes the superheated steam is desuperheated.

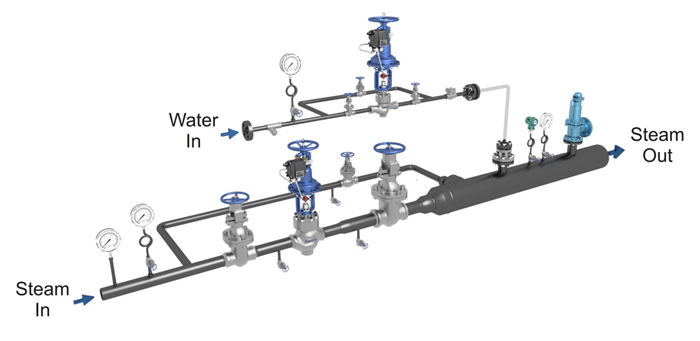

The equipment which is used to bring down the temperature of a superheated steam is called a steam desuperheater. The steam desuperheater is essentially a heat exchanger which uses a cooling medium in order to decrease the temperature of the superheated steam. Mostly the cooling liquid used to desuperheat a vapor is the same substance as the vapor. For superheated steam, the cooling liquid used is water.

Steam Desuperheater Working Principle

The principle is to spray liquid water in the superheated steam. This will lead to evaporative cooling effect as a major fraction of liquid droplets will evaporate. The evaporation of water requires heat which it will derive from its surroundings, that is, the superheated steam. This leads to decrease in temperature of steam as it exists the outlet of the steam desuperheater equipment.

Often it may happen that water may get accumulated at the walls of the equipment due to continuous operation. This accumulated water is removed by using hot water spray. The temperature of the hot water spray is maintained near the saturation temperature of the steam exiting from the outlet of the equipment.

Types of Steam Desuperheaters

Direct Contact Type:

The superheated steam and the cooling liquid water are contacted directly.

Indirect Contact Type:

The liquid water and the superheated steam are not contacted directly, a layer of solid separates the two fluids. Usually shell and tube heat exchangers are used for the process.

Integral Type:

The spray water valve is integrated with the equipment. It is already attached.

Non-Integral Type:

The spray water valve is not integrated with the equipment. It needs to be attached during the operation of the equipment.

Design Equations for Steam Desuperheaters

The turndown ratio describes the range of flow rates over which the desuperheater equipment operates. It is the ratio of maximum flow rate to minimum flow rate. Variation in flow rates causes variation in the requirement of amounts of cooling liquid. Two types of turn down ratios are to be specified in steam desuperheater equipment, they are; steam turndown ratio and cooling water turndown ratio.

The relationship between mass flow rates and specific enthalpies is given by:

M ̇_w=M ̇_s ((H ̂_s-H ̂_d ))/((H ̂_d-H ̂_w ) )

Here the subscript ‘w’ stands for cooling water, ‘s’ stands for steam and ‘d’ stands for desuperheated condition.

The cooling water volumetric flow rate, Q is given by:

Here, C is coefficient of discharge, A is area of orifice and g is the acceleration due to gravity and h is the head due to differential pressure.

Image credit:- electricalninstrumentcad exportersindia