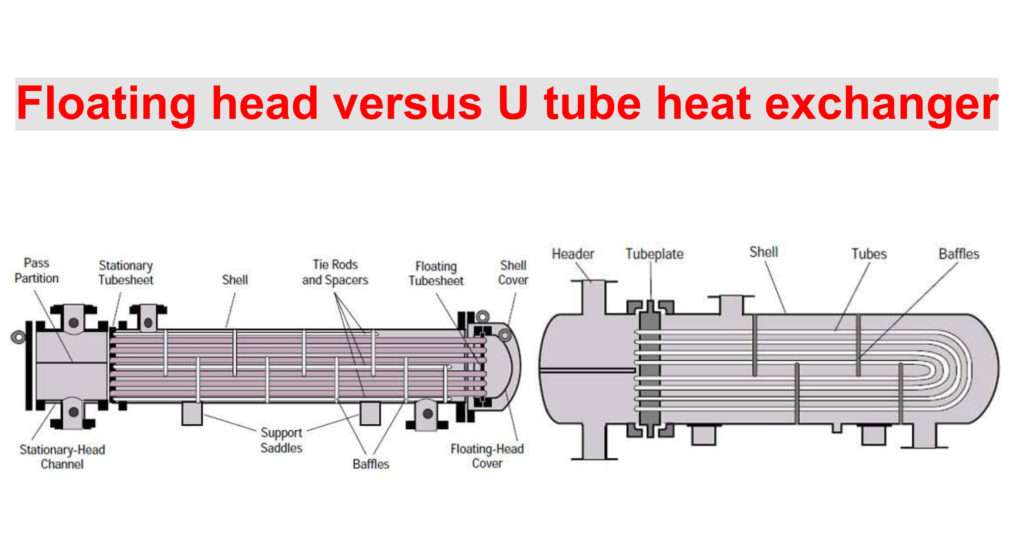

Floating head versus U tube heat exchanger

Floating head versus U tube heat exchanger

U tube heat exchanger

The tube bundle consists U shaped tubes. Both ends of U tube are fixed in the same tube sheet. Thermal expansion resulting due to the temperature difference between

shell and tube material is taken care off by U bends. U tubes can expand or contract freely and uniformly. It performs the same function as floating head. It also reduces the number of joints

Advantages:

- Initial cost is low.

- Internal gasket is eliminated.

- Only one tube sheet is required.

- Tube bundle can be removed for cleaning and inspection.

- By passing of shell side fluid is minimum due to minimum clearance between the shell and outer most tubes,

- It is easy to clean channel, tube side headers. Gaskets can be easily replaced.

Disadvantages

- Tube inner surface can be cleaned by chemical means only.

- .Individual tube replacement is difficult.

- Less number of tubes can be fixed on tube sheet because of U bends.

- Tube side passes can not be increased or decreased.

- Tube side velocity can initiate corrosion on the inside of bends.

Floating head heat exchanger

- Split back ring type

- Pull through bundle type

- Outside packed Lantern ring type

- Outside packed stuffing box type

Split back ring type unit is more commonly used in industries. In this type of construction straight tubes are fixed at both ends in stationary and floating tube sheets. Floating head is fitted to the tube sheet which is away from the channel. Floating head is held in position by a split backing ring so that dismantling is possible. Floating tube sheet diameter is kept slightly smaller than the inner shell diameter so that the entire tube bundle can be removed from the channel end. The shell is closed by a bonnet on the floating head side.

Advantages are that tube bundle can be removed for inspection and cleaning. Tubes can be replaced if damaged. Any number of tube side passes can be employed.

In this unit gasketted joints are very large, therefore it is costly. It is used below 70 kg/cm- pressures. Above these pressures floating head gasket may start leaking. Floating head heat exchangers are suitable for heavy duties associated with high temperature and pressure and large temperature differences. Fouling fluids can be handled because cleaning of tubes from inside and outside is possible. These units are widely used in petrochemical plants and chemical industries.

Advantages

- Tube bundle can be removed for inspection.

- Mechanical cleaning of the outer surface of tubes is easily possible.

- Since tubes are straight, individual tubes can be replaced. Inside tube surface can be

- cleaned without removing the tube bundle.

- No limitation on number of tube side passes.

Disadvantages

- It is very costly.

- It has a large number of gasket joints.