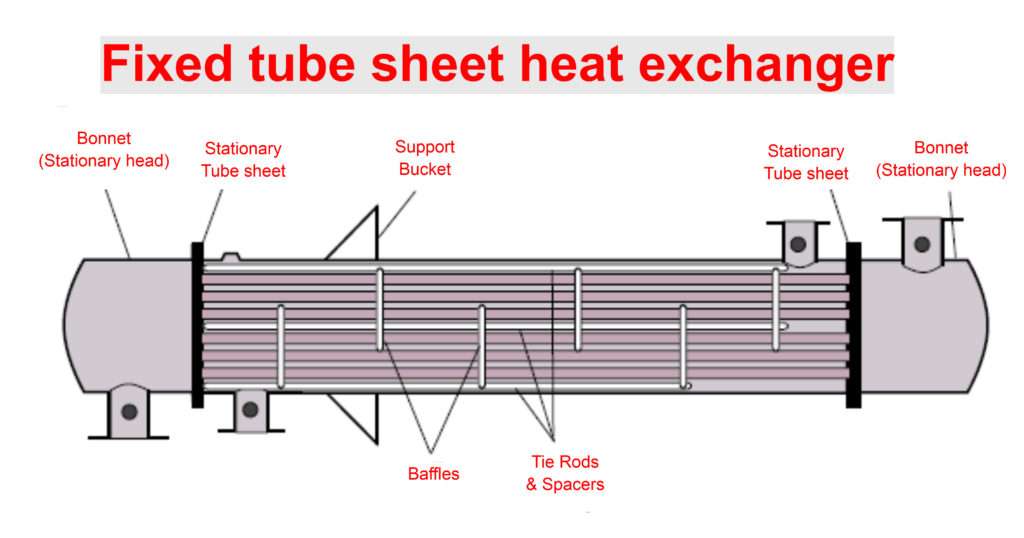

Fixed tube sheet heat exchanger

Fixed tube sheet heat exchanger

These are commonly used up to temperature difference of 90-95° C. Above these temperature differences problems of differential expansion arise. These are used when shell side fluid is clean and non-fouling.

Advantages and Disadvantages of Fixed tube sheet heat exchanger

Advantages

- It is simple in construction and economical.

- Gasketted joints are minimum.

- Shell is welded to tube sheet on both sides, so leakage possibility is less.

- No intermixing of shell side and tube side fluid.

- No limitation on number of tube side passes.

- Since straight tubes are used, tube replacement is easier.

- Tubes can be cleaned mechanically or chemically.

- Minimum by passing of shell side fluid between tube bundle and shell.

Disadvantages :

- It is not possible to remove tube bundle for inspection and cleaning.

- Outer surface of tube cannot be cleaned manually or mechanically.

- Shell and tube sheet material should be weldable together.

Reference:- Wiki