Venturi Meter versus Orifice Meter

Definition

Venturi Meter versus Orifice Meter:- Venturi meters and Orifice meters are devices which are used to measure average velocity, volumetric flow rate or mass flow rate of a flowing fluid by reducing the pressure of the flowing fluid. The pressure drop is mathematically related to the velocity or the flow rate of the flowing fluid by the continuity equation and the Bernoulli’s equation.

Structure

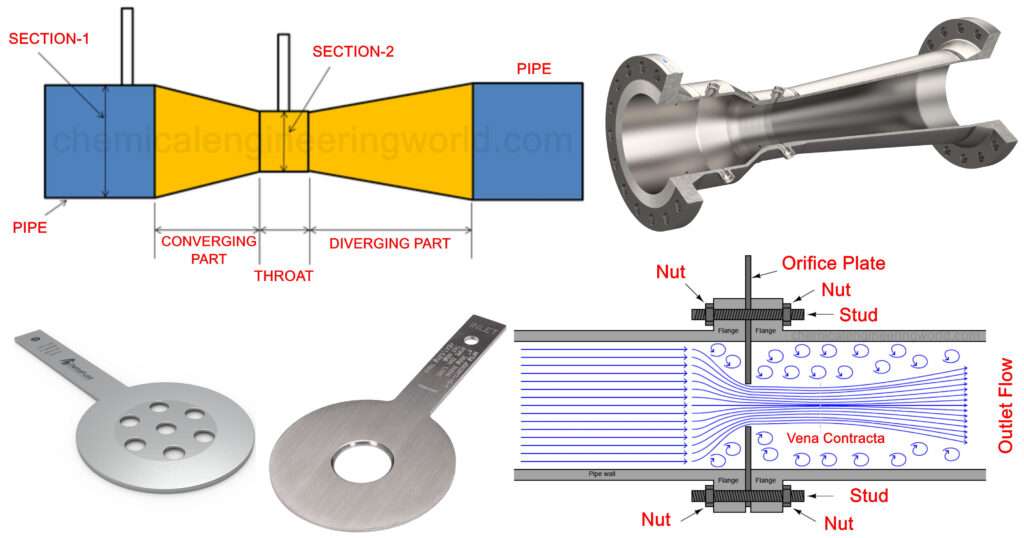

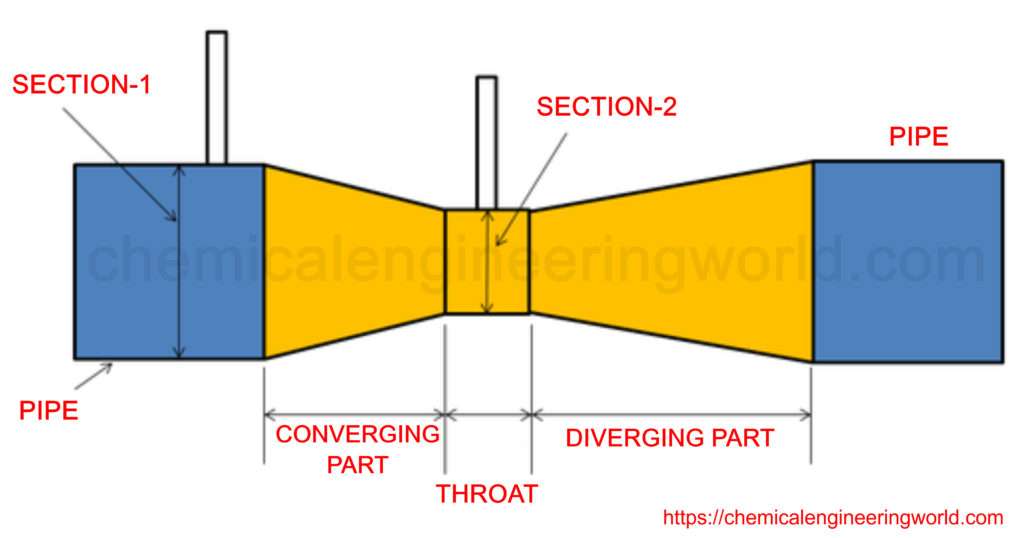

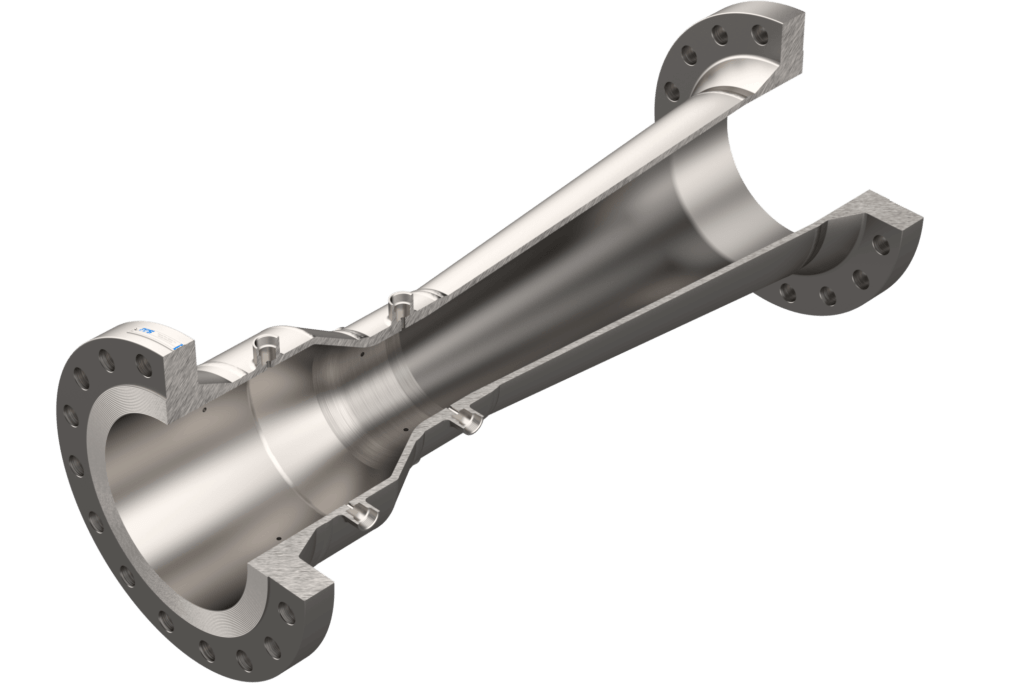

A Venturi meter is designed to have three parts; the converging section, the throat and the diverging section. Pressure taps are provided before the converging part and at the throat in order to measure the drop in pressure.

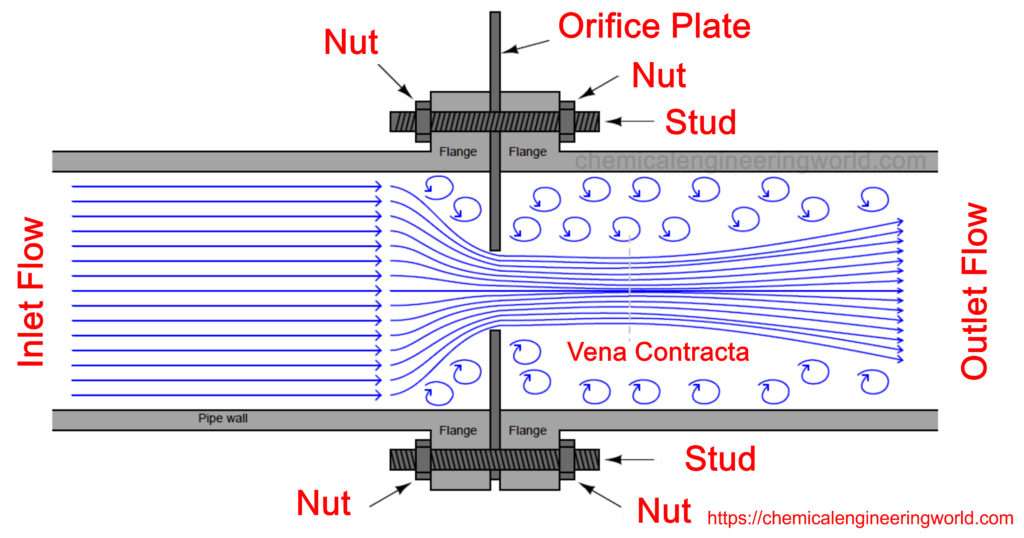

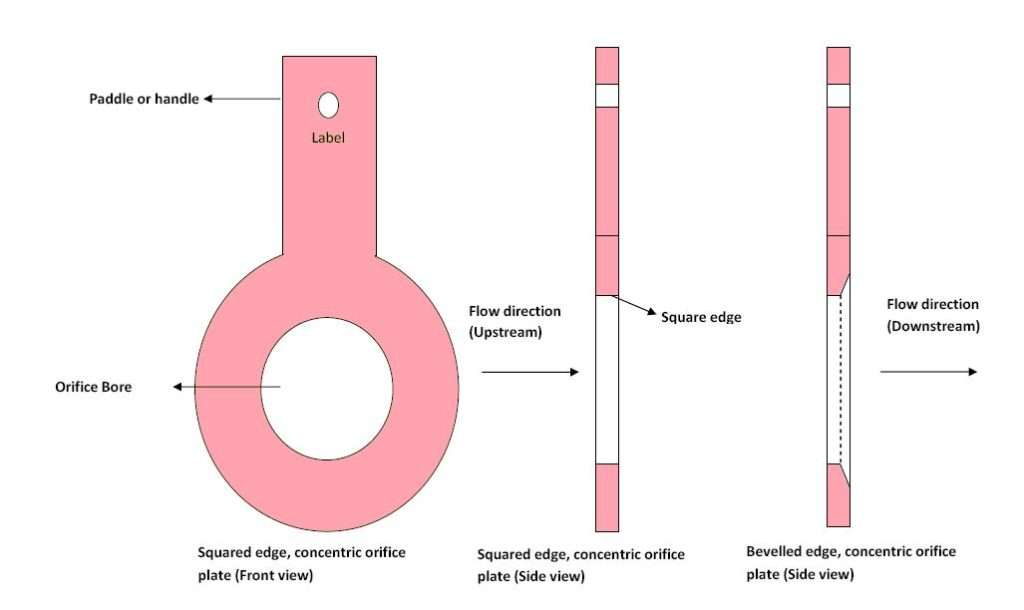

An orifice meter is consists a thin plate with a bore on the plate. This plate acts as a restriction. Pressure taps are provided before and after the orifice plate in order to measure the drop in pressure.

Working

In the Venturi meter; when the fluid reaches the converging part then according to continuity equation, when the cross sectional area decreases then the velocity of the flowing fluid increases. Bernoulli’s equation says that when the velocity of the flowing fluid increases the pressure of the flowing fluid decreases. This drop in pressure is used to calculate the average velocity or flow rate of the flowing fluid. The fluid then passes through the diverging section which is responsible for pressure recovery.

In the Orifice Meter; the flowing fluid starts to converge before it reaches the orifice plate and it continues to converge after passing through the orifice plate until a point called vena contracta is reached. The vena contracta is the point of maximum velocity and minimum pressure in the flow system. Principles of continuity equation and Bernoulli’s equation are applied here also in order to determine the average velocity and flow rate of the flowing fluid.

Pressure loss

In Venturi meter; there is a specific part called diverging section which is responsible for recovering the lost pressure which was affected due to the measurement of the average velocity or flow rate of the flowing fluid. The pressure loss is about ten percentages (10%).

In Orifice meter; the pressure loss is relatively more compared to Venturi meter because it contains no specific part which is aimed for pressure recovery. The pressure loss is fifty to sixty percentages (50-60%).

Coefficient of Discharge

The Coefficient of Discharge is the ratio between the actual discharge measured by experiments and theoretical discharge calculated by equations.

In Venturi meter; the value of coefficient of discharge can be up to 0.98, it is relatively high.

In Orifice meter; the value of coefficient of discharge is in the neighborhood of 0.6, it is relatively low.

The Turn Down Ratio

Turn Down ratio is the ratio of the maximum capacity to minimum capacity. It signifies width of the operational range of the device.

In Venturi meter; the turn down ratio is 10:1

In Orifice meter; the turn down ratio is 5:1

The inclination of pipe

The Venturi meter can be installed in pipes which are oriented horizontally, vertically or is inclined at any angle. The Venturi meter is insensitive to changes in velocity vector. The pipes in which Venturi meters are installed need not be straight.

The Orifice meter is compulsorily to be installed on the pipes which is straight. The velocity vector of fluid must be perpendicular to the orifice plate for lower pressure loss and better accuracy in measurement of average velocity or flow rate or the flowing fluid.

Clogging Problems

Clogging problem is liable to occur in cases when the working fluid is a fluid which contains particulate solids or when the working fluid is slurry.

The Venturi meters can be easily used for such working fluid because the very geometry of the Venturi meter prevents any kind of accumulation or clogging. The flowing fluid follows the streamline design and the particulate solids are swept with the fluid itself.

The Orifice meter is generally not used for such working fluids because the design of the obstruction creates dead zones where the solids may deposit and accumulate overtime. Also clogging may occur if bore size is too small for the solids present in the slurry. If at all orifice meters have to be used in systems containing slurry then an eccentric orifice plate is used with the bore at the bottom of the plate.

Operational Flexibility

The Venturi meter can handle large range of flow rates of fluid than the Orifice meter but once the Venturi meter is installed the range of flow rates it can handle becomes fixed.

In the Orifice meter, the orifice plates can be easily removed and changed with a different orifice plate which contains different bore size or arrangement. Thus, Orifice meters offer much more flexibility of operation.

Cost of the device

The design of the Venturi meter is complex. A complex device has a larger fabrication cost and maintenance of Venturi meter also costs more and is relatively difficult.

The usage of type of fluid: Liquid or Gas

The Venturi meter is used for operating in-compressible fluids. In-compressible fluids are liquids and the flowing gases whose value of Mach number is less than 0.3

The Orifice meter is generally used for Liquids only.