Orbit valves Introduction

know about Orbit valves

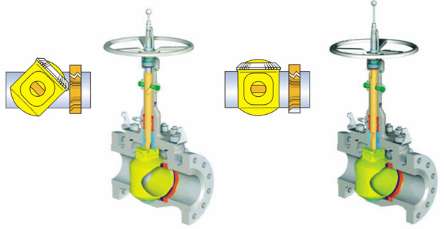

Operating Principle

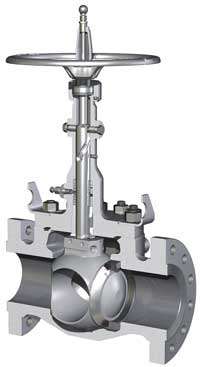

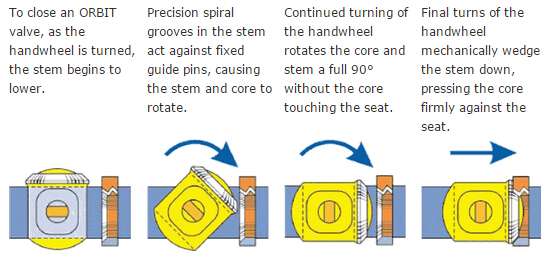

Every ORBIT valve incorporates a tested tilt and switch operation that eliminates seal rubbing, that is the primary reason for valve failure.

When an ORBIT valve is closed, the core is automatically stuck tightly against the seat, ensuring positive shut-off.

When an ORBIT valve begins to open, the core tilts far from the seat and line flow passes uniformly round the core face.

This eliminates the localized high speed flow that generally creates uneven seat wear in standard ball, gate and plug valves. The core then rotates to the complete open position.

The absence of seal rubbing throughout each opening and shutting means that simple, low torque valve operation and long run reliable performance. Once valve leak can’t be tolerated, the ORBIT operational principle may be relied upon to deliver a positive shut-off.

Product range and choices

ORBIT valves are manufactured much kind of materials, sizes and trims to fulfill specific necessities.

Materials

Carbon steel, stainless-steel, duplex SS, high nickel alloys and different special materials are used as service conditions need. Internal and external protecting coatings are offered for more strength in corrosive conditions.

Seats

Soft or metal seated choices are designated for the intended service. Due to the seals in the valves don’t rub and because they’re automatically compressed shut, they survive in extreme temperature and abrasive conditions

Operation

Hand or power operation will be designated. ORBIT builds double acting, spring shut and spring open pneumatic actuators. User designated electrical and hydraulic actuators are offered. Huge instrumentation selections are offered.

Customizing

Hand wheel extensions, safety interlocks, position indicator limit switches, thermal jackets, custom painting and special review will be provided.

Some Key options of Orbit valves.

Some Key options of Orbit valves

- Multiple sizes and pressure ratings

- Raised face flange

- -155 ° F to 800 ° F (-104 ° C to 427 ° C) operational temperatures

- Applications embody hot oil systems, mole sieve dryers and equipment isolation

- distinctive design automatically energizes seal by cam action

- Single-seat design

- Bi-directional sealing with zero leak

- injectable packing

- Self-cleaning

- In-line serviceable

Reference:- wermac