Rotating Disc Contactor

Rotating Disc Contactor:- Extraction is a process in which the components of interest in a liquid mixture are separated by contacting the feed liquid mixture with another liquid called solvent and mixing both the liquids thoroughly. The components of the feed liquid mixture will redistribute themselves between the feed itself and the solvent.

The purpose of extraction can be either to remove impurities from the feed liquid mixture or to separate the valuable components from the feed liquid mixture

Rotating Disc Contactor (RDC) are columns which are used for liquid-liquid extraction process and they are widely used in chemical industries. They are usually used to remove impurities from liquid mixtures. The extractor was developed in 1950s by Shell Company, Netherlands. Rotating Disc Contactor (RDC) is a type of equipment which operates on the principle of agitation.

Structure of Rotating Disc Contactor

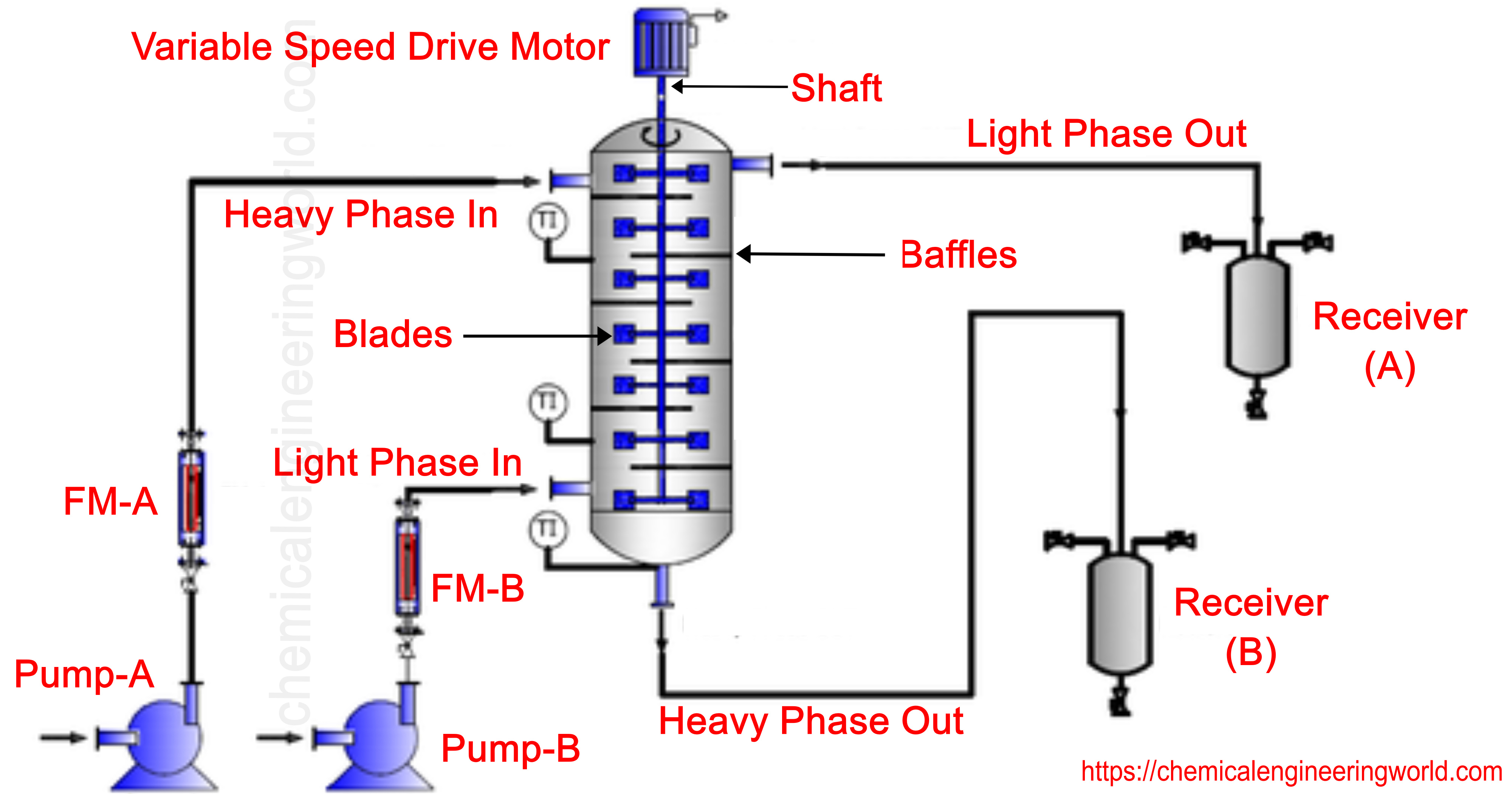

Rotating Disc Contactor are long cylindrical columns which are mounted by a shaft at the centre of the column. The shafts are attached to motors in order to rotate it and variable speed drives are used in order to vary the speed of the rotation of the shaft.

The entire column is divided in to several equally spaced compartments by using several stator rings. Stators are the stationary parts of the rotating equipments; in fluid devices they are used to direct and redirect the direction of the flowing fluid smoothly.

A rotating disc is placed at the centre of each compartment. Each compartment has one rotary disc associated with it. The discs are mounted on the shaft.

The inlet for the heavy liquid is placed on the upper section of the column and the outlet for the heavy liquid is placed at the bottom of the column. The inlet for the light liquid is placed on the lower section of the column and the outlet for the light liquid is placed on the top of the column.

Working of Rotating Disc Contactor

The heavy liquid is input in the column from upper section of the column. The light liquid is input in the column from the lower portion of the column. Due to differences in densities, the heavy liquid falls from upper section of the column to lower section of the column due to effect of gravity and in the process it displaces an equal volume of the light liquid. In this way they are contacted.

The effect of agitation inside the column due to rotation of the shaft increases the rate of mass transport of the component or the components of interest from one phase to another. Agitation makes it easier for one liquid to get dispersed into the other liquid in form of fine droplets.

The rotary discs which are mounted on the shaft break the droplets by shear force thus helping in the process by making droplets even finer. The finer the droplets better the rate of mass transport of the component of interest between the phases.

Modification of Rotating Disc Contactor

Asymmetric Rotating Disc Contactor (ARDC) is a modification of Rotating Disc Contactor (RDC) in which the shaft is centred off centre or eccentrically. Doing this leads to sufficient decrease in solvent usage and also sufficient reduction in power required.

Image:- Indiamart