Thermosyphon Reboiler

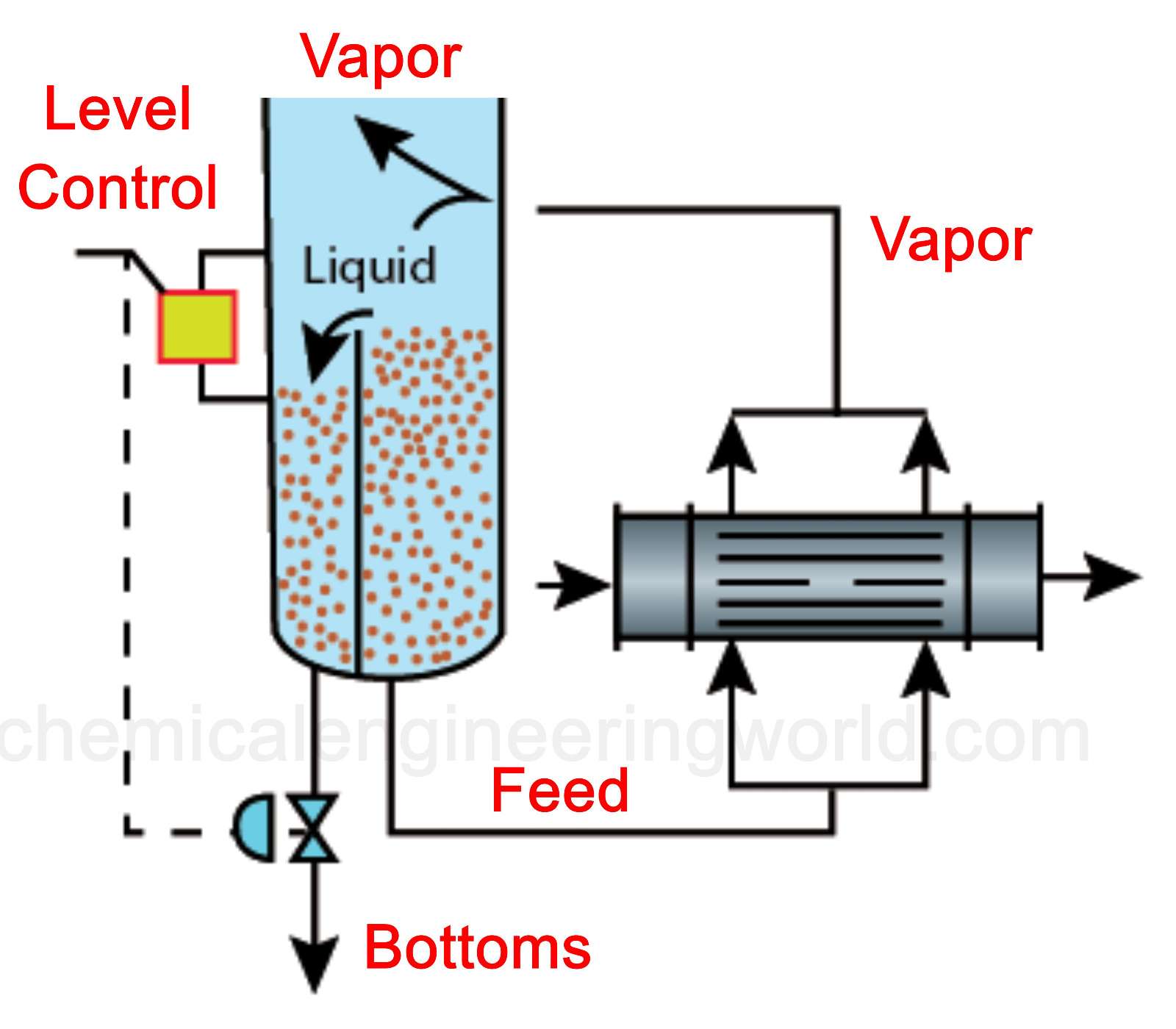

Thermosyphon Reboiler:- A reboiler is an equipment which is installed with the distillation column and its purpose is to convert the liquid which is provided by the bottom tray of the distillation column into vapours. These vapours are then returned to the distillation column. A reboiler is essentially a heat exchanger.

The name thermosyphon is made up of two words; ‘thermo’ meaning relating to heat and ‘syphon’ means transfer of a fluid from one place to another by means of suction or immersion. In thermosyphon reboilers, natural circulation is obtained by using the density difference between the reboiler column bottoms liquid and the reboiler outlet vapour-liquid mixture to provide sufficient liquid head to deliver the tower bottoms into the reboiler.

There are mainly two types of thermosyphon reboilers:

- Vertical Thermosyphon Reboilers.

- Horizontal Thermosyphon Reboilers.

1. Vertical Thermosyphon Reboilers

A vertical thermosyphon reboiler consists of single pass tube bundle and it is covered by TEMA E-shell. The tube bundles are placed vertically such that the axis of the tube is perpendicular to the ground. The liquid which is to be boiled usually flows through the tube side. The heating fluid is usually passed through the shell side, the role of the heating fluid is to provide energy to the boiling liquid so that a fraction of the liquid flowing through the tubes will get vaporized. The two phase fluid then flows in to the distillation column where it gets separated.

The liquid in the column is usually maintained at the level close to the tube sheet to provide adequate static head. When operating at vacuum, the liquid level is kept at 50-70% of the tube height to reduce the boiling point elevation of the liquid fed to the reboiler.

Advantages of Vertical Thermosyphon Reboiler

- These reboilers can be attached directly to the column so the cost of support structure and piping are minimized and also a part of plot space is saved.

- Relatively high velocities are attained which helps in minimizing fouling.

- The TEMA E-shells are relatively inexpensive.

Disadvantages of Vertical Thermosyphon Reboiler

- Due to large static head, the boiling point increases.

- Vertical configuration makes maintenance more difficult.

2. Horizontal Thermosyphon Reboiler

The tube bundle and the shell in horizontal thermosyphon reboiler are placed such that their axis are parallel to the ground. The shells can be of the type TEMA G, TEMA H or TEMA X. The tube passes can be configured for single pass or multiple passes.

If it is configured for multiple passes then U-tube types can be used. The boiling liquid is fed in the shell side and the heating fluid flows through the tube. Boiling takes place on the exterior of the tube surface and the boiling liquid is then returned to the column. This type of boiler is usually a choice when viscosity of the boiling liquid is relatively high because relatively small static head is required to overcome the fluid friction.

Advantages of Horizontal Thermosyphon Reboiler

- It is relatively easier to remove the tubes and clean them.

- It is relatively more effective at low temperature differences.

Disadvantages of Horizontal Thermosyphon Reboiler

- The process fluid on the shell side leads to fouling.

- Relatively larger plot area is required for installation.