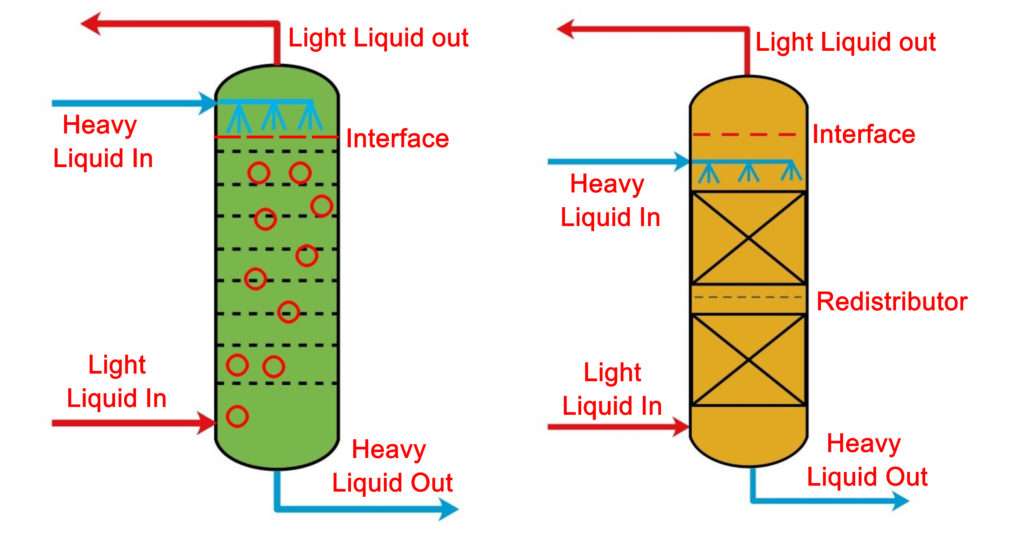

Spray Towers/wet scrubber for Extraction

Spray Towers/wet scrubber:– Extraction is a process in which the components of interest in a liquid mixture are separated by contacting the feed liquid mixture with another liquid called solvent and mixing both the liquids thoroughly. The components of the feed liquid mixture will redistribute themselves between the feed itself and the solvent.

The purpose of extraction can be either to remove impurities from the feed liquid mixture or to separate the valuable components from the feed liquid mixture.

Spray Towers are one of the simplest equipment which are in use in industries. They are generally used for very simple applications like washing, they are relatively more common in gas-liquid contact industries and they are mostly used as direct contactors for the process of heat exchange.

Structure of Spray Towers

Spray towers are long columns with very simple design. They do not contain any moving part.

They contain spray nozzles in the top of the column in order to spray the liquid. Other variation consists of a tower which contains perforated pipes at the bottom of the column.

Working of Spray Towers

The heavy liquid is input in the tower from the top of the column. It is passed through the spray nozzles. The effect of the spray nozzle is that it makes the heavy liquid phase discontinuous or in form of droplets. The light liquid is input from the bottom of the column and it is a continuous phase.

Due to the effects of gravity the heavy liquid falls from the upper section of column to lower section of the column and in doing so it displaces an equal volume of light liquid. The light liquid rises up accordingly and due to this contact mass transport of the component or components of interest occurs between both the liquid phases.

Due to the spray nozzle, the heavy liquid is dispersed into the light liquid. It means the heavy liquid exists as a dispersed phase in the emulsion and light liquid exists as a continuous phase in the emulsion.

A modification in a tower could be to use perforated pipe at the bottom of the column. The light liquid is passed through the perforated pipes. The effect of the perforated pipe is that it makes the light liquid phase discontinuous or droplet like. The heavy liquid is input from the top of the column. In this case the heavy liquid is the continuous phase in the emulsion and light liquid is the dispersed phase in the emulsion.

The flow rates of the heavy liquid and the light liquid greatly depend on the densities and viscosity of the liquid phases.

Advantages of Spray Towers

- There are no moving parts or internal parts except spray nozzles or perforated pipes hence problems of scale buildup and plugging are automatically eliminated.

- They are very simple to design, construct and erect.

Disadvantages of Spray Towers

- Plugging problems may take place in the spray nozzle or perforated pipes.

- Considerable back mixing occurs in tower which reduces the rate of mass transport.

- The small rate of drop breakage also leads to low mass transport rates.