Automatic Recirculation Valve

What is ARV or ARC valves?

ARV valve is known as Automatic Recirculation Valve.

An automatic recirculation valve could be a valve whose primary purpose is making sure that a per-determined minimum required flow is assured through a pump in the least times. This can be necessary as centrifugal pumps suffer from overheating and cavitation and may be permanently broken if they dry out.

ARC valve is that the abbreviation for Automatic Recirculation control valve, and ARC® could be a registered name of Yarway. As per operatibility of this Valve is that the similar as that of a AR valve.

Centrifugal Pump Protection situations

Centrifugal pumps rework mechanical energy into pressure energy by means that of centrifugal force ensuing from blade rotation working on the fluid inside the pump. The pump needs a minimum liquid flow so as to avoid warming. If a predefined minimum flow isn’t maintained, the pump may be permanently broken. a number of various pump protection situations are reviewed below.

Non come back situation:- The pump has no back-flow prevention and so product can flow back through it once it’s stopped. A non-return valve (NRV) is thus typically placed when the outlet of the pump. A reservoir is employed to require the pumps output once there’s no process demand.

Continuous flow situation:- a manual bypass or outflow path will be added to permit the desired minimum flow back to the pump inlet. This method is very smooth and efficient, however is in steady operation and thus is inefficient and expensive (energy costs).

Control valve situation:- this comprehensive control valve resolution is extremely effective. During this circumstance, a flow control valve is hooked up to a flow meter and allows the most line flow to be metered. As path flow decreases the control valve opens to permit the right minimum flow needed. However, it’s an extremely capital intensive resolution that needs flow metering equipment, control and non-return valves. No reservoir is needed.

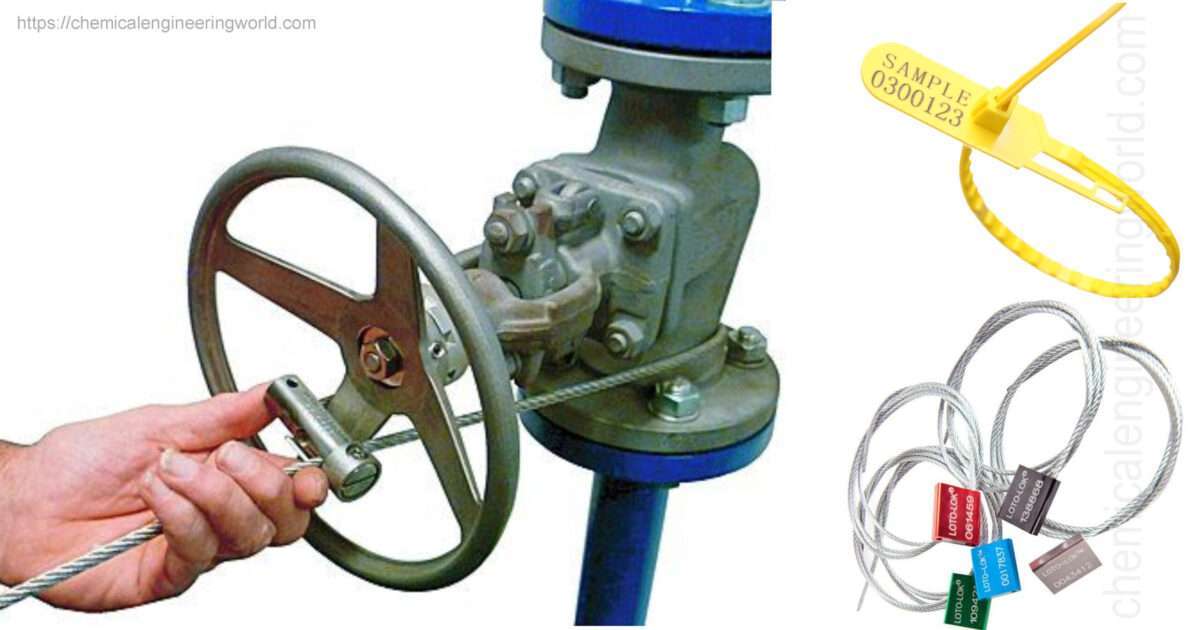

ARV resolution:- the previous approach stands and falls with the integrity of the system and its associated price. A safer system is to mix the non-return valve, the bypass valve and also the control valve into an interconnected unit, the therefore known as “automatic recirculation valve”. This valve closes once there’s no flow, mechanically opening the bypass line that is sized for minimum flow. Once the most line takes flow however but minimum, the bypass line and therefore the path are each partially open.

Operation of an Automatic Recirculation Valve

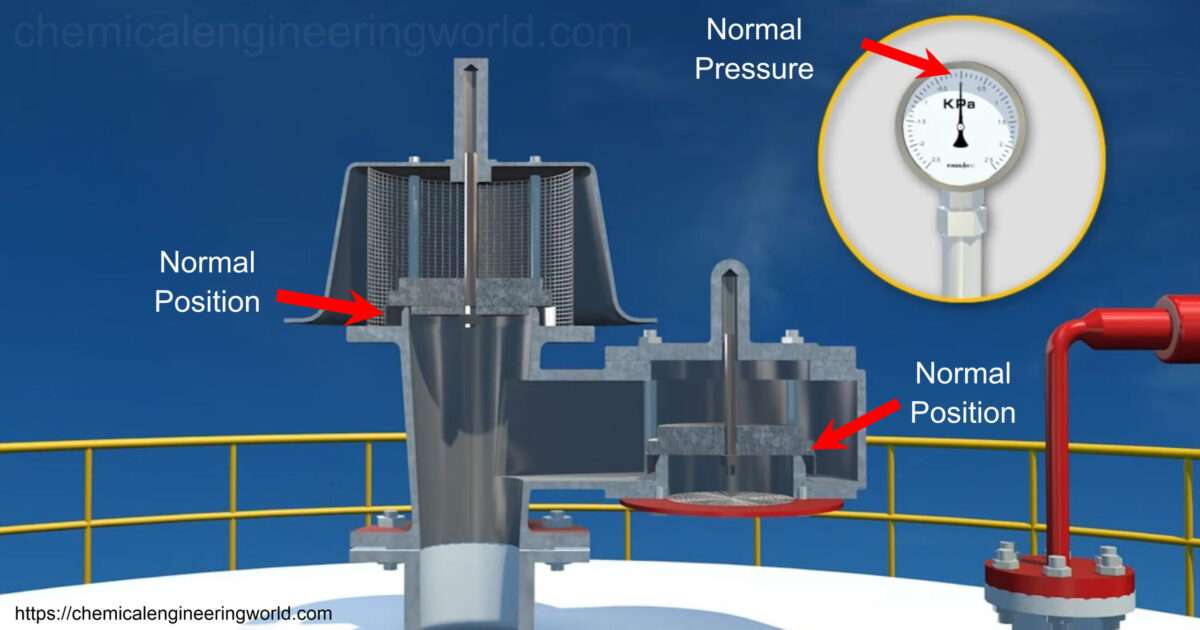

The heart of the recirculation valve could be a main flow sensing check valve disc, that is flow sensitive, not pressure sensitive. The disc modulates to the demand for process flow at an equivalent time serving to guarantee a minimum flow through the pump. This modulating characteristic leads to a uniform, stable, and repeatable performance over full pressure range.

- Once the disc is set at full raise position, as in Figure one, the bypass is closed. As process flow decreases, the reverse action happens and therefore the recirculation flow once more will increase. Flow enters the bypass component at the lowest of the disc assembly and is controlled by characterized orifices within the disc stem. Flow continues through an annulus within the bypass bushing and is directed to the outlet of the valve. The valve provides for single part flow within the bypass, eliminating the chance of flashing or cavitation. This can be accomplished by the valve style, and if necessary, external back pressure regulator.

- Because the disc lifts (Figure 2) in response to a rise in flow to the process, the bypass component that is integral to the disc, closes the bypass flow orifices reducing recirculation flow. Recirculation flow is controlled with disc position. This modulation feature assures that the whole of process flow and recirculation flow exceeds the minimum flow through the pump as nominative by the pump manufacturer.

- The disc is shown within the closed position in Figure three. During this position there’s no process flow and therefore the bypass is totally open. This protects the pump against planned or accidental “dead heading” which might result from a closed down stream pump isolation valve or process control valve.

Reference:- wermac