Corrugated Plate Interceptor

Corrugated Plate Interceptor Introduction:-

The CPI (corrugated plate interceptor) Oil Separator is appropriate for oily wastewater treatment, utilizing the principle of gravity to separate oil and water. The CPI is designed and intended to separate oily wastewater in the lighter oily fraction and the heavier water fraction. The simple arrangement of this innovation makes it possible and conceivable to minimize construction costs and improve maintenance. Aside from the ability to provide high oil-water separation efficiency, this arrangement makes it conceivable to consistently treat water in any event, when how much rainwater is to be dealt with is two or even multiple times larger than expected.

What are corrugated plate interceptors?

The most well-known and efficient system utilized in oil facilities is the corrugated Plate Interceptor (CPI). CPI utilizes the guideline of gravity to separate oil wastewater into the lighter oil fraction and the heavier oil fraction. The heavier fraction will be separated and sink to the base. This is an improvement in the shape/model of the PPI which requires a small region to move a similar particle size and has the additional benefit of making the following silt simpler to deal with. The plate packs make a successful detachment surface up to multiple times (50 times) the impression of the CPI. The corrugated Plate Interceptor (CPI) is a high-rate oil/water separator appropriate for different industrial applications. As in separation systems, CPI units are built for the operator’s benevolence. Simple support and maintenance, minimal moving parts, and process versatility are signs of the CPI design approach. CPI units can be fitted with a rotating or turning skimmer or a static skimmer.

At the core of the oil separator is the corrugated plate interceptor (CPI) plate pack. The plate pack design limits the distance a free oil droplet should ascend prior to coming into contact with other oil droplets. This design ensures that the oil drops mix on the undersides of the corrugated plates, which facilitates the free oil evacuation process.

The CPI oil-water separator series is designed and intended to create the best conditions for the simple separation of both water and oil. The installed corrugated lamella plate packs create a large effective surface region, creating a high separation area. The separated oil is collected or gathered with a skimmer pipe and can be released with a pump.

The corrugated plates are organized with short void space or plate pack media. It is utilized for providing high oil-water separation efficiency because of the narrow passage. This further helps with capturing the floating solids to go upwards and settles them down which is taken out or eliminated from the base channel. The plate packs utilized are of inert MOC to avoid corrosion.

Contrasted or Differentiated with the PPI (Parallel Plate Interceptor), the CPI Oil Separator requires a small impression. Different benefits incorporate low capital expense, simple structure, and facilitative maintenance.

How corrugated plate interceptor work?

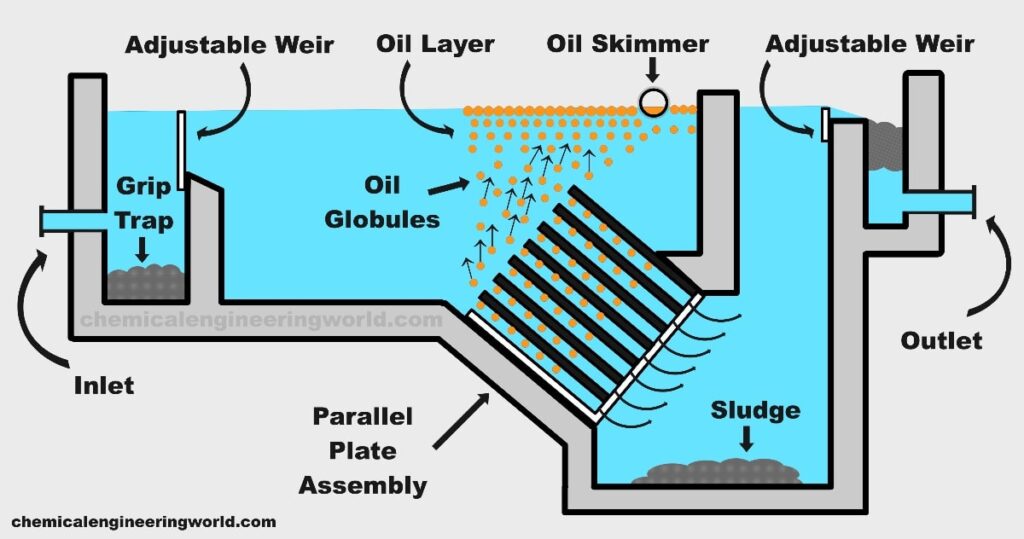

This is a refinement of the PPI in that it takes up less plan area for a comparable particle size evacuation, and also has the additional benefit of making sediment or residue dealing simpler. Waste water enters the inlet nozzle into an extended blending segment. This coalescing section is where heavier solids and muck settle out of the waste water to the lower part of the vessel where it is discharged through the clean out nozzle.

After it is equitably dispersed, it flows down through the pack where oil ascends to the highest point of the corrugations and blends with other oil drops. The large oil droplets ascend through the plate pack to the oil/water interface. Coalesced oil will flow over an inside adjustable oil weir and is removed through the oil outlet nozzle. Light solids and sludge separation is all the while accomplished within the pack by settling to the lower part of the corrugations where solids are directed to the ooze sludge drain. The flow out of the plate pack goes vertically and pours out over a fixed water weir, then, at that point, exits the vessel through the water outlet nozzle for additional downstream treatment or removal.

Where corrugated plate interceptor is used?

Corrugated Plate Interceptor CPI design configuration is utilized to eliminate bulk oil from the water utilizing combination and separation, combined with solids jetting systems, oil and solids are taken out from the water. CPI (corrugated Plate Interceptor) separators are utilized in the separation of free oil or emanating water or suspended solids for oily water treatment in an oily Water system. The central standard of difference or distinction in gravity between the phases is utilized in an oil water separation of the two phases. Obviously, the phase with high density will settle and with lower density will drift to the outer layer of fluid. In an OWS, the effectiveness of this method is subjected to different factors like density difference, the viscosity of the oil, variables of the medium, temperature, turbulence, and furthermore the nature of impurity and so on. In a few cases, chemical coagulation and flocculation are required for the expulsion of the impurities by making them heavier. In the separation technique, while considering the above-alluded factors, which influence the separation of impurities, an overflow rate (m3/m2/day) or settling velocity (m/hr.) is arrived at. This factor concludes the surface area which is required for the separation in an oil water separation. It just so happens, that it additionally underlines the point that gravity separation is free of the depth of the basin. However, while saying as much, one should remember that quiescent circumstances are expected for good settling.

The CPI (corrugated plate interceptor) is overwhelmingly utilized in the separation of free oil and suspended solids from produced or oily wastewater. CPIs are utilized to eliminate free and floating sort of oils. It deals with the fundamental guideline of contrast in gravity between the phases (liquid or solid fluid). CPI Oil Separators empower high-proficiency gravity separation with corrugated plates, furnishing phenomenon treatability with a high flow rate. The simple structure makes it conceivable to diminish the construction cost and facilitates maintenance.

The figure displayed underneath is the design type of the CPI while. The plate pack has a 45 ° angle and the water flow pattern moves down the plate. The oil attached to the plate will move and ascend to the surface and gather at the oil collection site. Hence, there is the possibility that the grains of sand are attached and will ultimately clog the plate, resulting in turbulence flow and in the long run can flow. To wipe out the above issues, an “up-flow” flow pattern made using the base-up should be finished. CPI units utilized are designed at 60°.

What are the advantages of a corrugated plate interceptor?

(i.) Corrugated plate interceptor required Low space.

(ii.) Corrugated plate interceptor requires extremely less maintenance, and low capital, and operation costs.

(iii.) There is High efficiency and capacity combined with compact volume.

(iv.) Corrugated plate interceptor has low installation costs since units are generally prefabricated.

(v.) Handles shock loads or heaps of flow without influencing emanating quality.

(vi.) Corrugated plate interceptor has continuous activity without significant downtime.

(vii.) Intensive toward weather conditions, variation in temperature, and composition of the incoming liquid. (viii.) The corrugated plates are located at short spans, providing high oil-water separation effectiveness.

What are the disadvantages of corrugated plate interceptors:-

(i.) The effluent oil concentration is higher than that of different strategies.

(ii.) Large surface area is required in corrugated plate interceptor

(iii.) In corrugated plate interceptors large volume results in dead zones and the reduction of net available surface area.

(iv.) Expensive oil/bottom scrapers required that are maintenance intensive

(V.) Ineffective with small oil droplets or emulsified oil, Requires a long retention time to achieve efficient separation.

What is the use of oily water treatment in corrugated plate Interceptors?

In oily water treatment, tilted or moved (set in predetermined angles) plate packs are used in CPI/TPI separators to chip away at the size and economy of the separator system. As corrugated plate packs are prevalently used, the tilted plate pack type separators are notable as corrugated plate interceptors or similarly as CPI separators. Regardless, a TPI (Tilted plate interceptor) may use a corrugated type plate pack or essentially plain parallel plate pack. Subsequently, TPI separator is a generic terminology utilized in such sorts of separators. The separator when used in the separation of fluid, liquid phases is known as a TPI (Tilted plate interceptor) or a CPI separator. Any separation of suspended solids in oily water treatment by usage of CPI corrugated plate interceptor)/TPI (Shifted plate interceptor) separator is coincidental in light of the differentiation in gravity between the effluent liquid phase and the solid stage.

The corrugated plate pack in a TPI/CPI separator, that is utilized in oily water treatment for clearing free from free oil, that contain number of parallel corrugated plates. A Plate pack is a housing of flat plastic plates and set by a frame made utilizing plastic material or stainless steel.

The quantity of plates in a Plate not entirely determined by various estimations or calculations as well as based on experience with various effluents and applications. The number of plates per Plate pack is likewise considered partially on the economy of the size of the separator. The quantity of Plate packs per TPI/CPI separator is determined considering the effluent flow and its qualities to the unit.

The liquid or fluid to be dealt with flows through the spaces between the corrugated Plates in each Plate pack. The Ideal condition for separation is accomplished in the TPI (Tilted plate interceptor)/CPI (corrugated plate interceptor) separator by simulating a laminar flow condition through the plate pack. To lessen the frictional resistance between the separated material and the corrugated plates to a minimum, specific consideration should be paid to the perfection and hardness of the plate surface. The corrugated Plates as well as the casing of the Plate Pack of the TPI/CPI separator are by and large made using glass fiber-reinforced polyester sap. This material is resistant to the most often used chemical additives and temperature as well as effluents to be dealt with or treated.

Conclusion:-

The corrugated Plate Interceptor is a gravity separator. The CPI is designed to separate or isolate oily wastewater in the lighter oily fraction and the heavier water fraction. The heavy particles will be separated also and sink to the lower part of the CPI. The CPI is designed to separate oily water on a small footprint, utilizing plate pack technology and a high-level distribution system to improve the separation conditions. The plate packs create an effective separation surface up to multiple (50) times the footprint of the CPI. Compared or Contrasted with the parallel Plate Interceptor, the CPI Oil Separator requires something like 2/3 the installation area, compact design clears out any concern about plastic deformation. Subsequently, the CPI Oil Separator has a somewhat low development cost. The CPI Oil Separator uses a molded or shaped synthetic resin that is exceptionally impenetrable to corrosion, and solvent base, as FRP and is suitable for water quality.

Reference:- cecoenviro, vishuddhienviro, neotechwater