Burner Working & Types

Burner Working & Types

Burner Working & Types

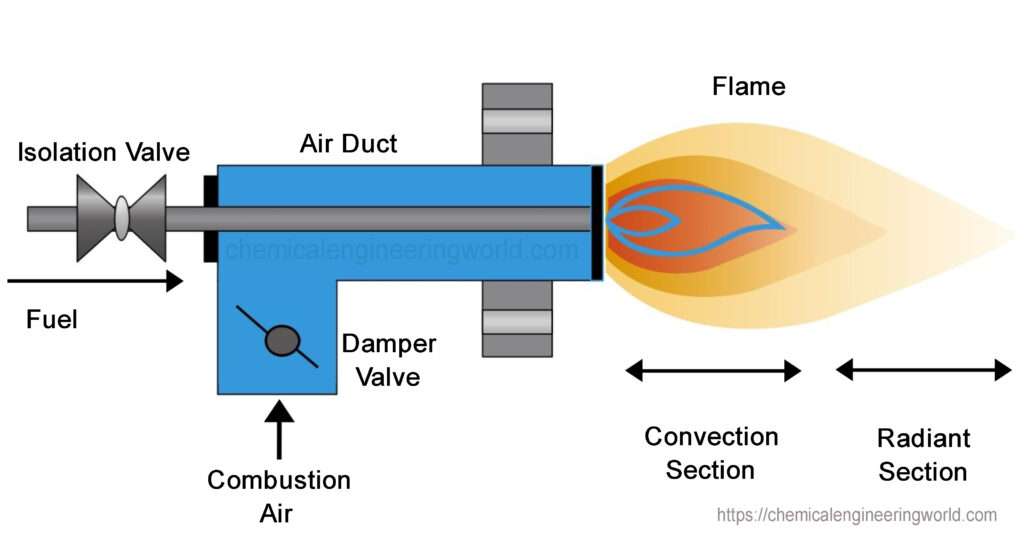

Burners are mechanical devises which are used to control the air and fuel mixture so that if the mixture is burnt then the flame is also sustained for as much time as required for a task. Combustion is a high temperature exothermic redox reaction carried between a fuel and an oxidant to produce gaseous products along with heat and light energy. Essentially burners are devices which are used to sustain combustion reactions for the purpose of heating fluids or carrying out endothermic chemical reactions or converting liquids into vapours etc.

The burners which are used commonly in labs are called Bunsen burners. It is simply a tube which is connected to a supply of fuel. The fuel is gaseous in nature. The flow of fuel supply is regulated by a valve, usually a needle valve. When the valve is opened, the gas flows through the tube. The gas leaving out of the tube can be ignited, once ignited a flame appears at the top because the gas starts burning. The gas burns only at the top portion of the tube and not in inside the tube because sufficient oxygen is only available at the top portion of the tube. It is a handy and simple device used for heating, sterilization and combustion tasks at lab scale processes.

Industrial burners are much more large and complex in nature. Some of the types are:

Burner Types

- Air Staged Burners

- Regenerative Burners

- Self-Recuperative Burners

- Radiant Tube Burners

Air Staged Burners

All the fuel is mixed with some quantity of air through inner air jet and then as required by the combustion process, air is supplied from outer air jets in stages.

Regenerative Burners

They use a pair of burners which operate together in order to increase thermal efficiency of the system. The exhaust gas from one burner is used to heat the air which is about to be fired in the other burner and vice versa. Thus they operate in an alternate cycle.

Self-Recuperative Burners

This burner has a recuperating action installed. The exhaust gases are pulled back through an educator and the air is which is incoming is heated using the exhaust gases.

Radiant Tube Burners

All the previous burners had the fuel and air mixture burning in presence with the load, the raw material. In radiant tube burners, the process of combustion happens in a tube, the tube serves as a boundary which separates fuel air mix and the load. The heat is transferred to the load via radiation.

Burner Management System (BMS)

A burner management system is a system which is used to manage the startup, operation and shutdown of industrial burners so that it is safe to function. It is able to manage any equipment which uses flame like furnace, boilers etc. The system manages flame, igniter, burner and actuator.

The burner management system mainly performs these functions:

- Prevents startup of the equipment until certain permissive interlocks have first been completed and it can also inhibit the startup if certain required conditions are not met.

- It prevents firing of the equipment unless and until satisfactory purge has been completed.

- When the burning operation begins then it sustains it conditionally only if certain safety interlocks are satisfied. It can detect unsafe operating condition and can even protect from these conditions.

- Provide the information of the condition of the various components to the control room and data logging.

Reference:- instrumentationtools, bloomeng