Deluge Valve System Working

Deluge Valve System Working

Deluge Valve System Working

Deluge valve systems are a set-up which causes a large volume of water to be delivered to a large area in a quite short amount of time. Due to this they find wide applications in all the industries where there is a high chance of a device or an equipment catching fire. In essence, due to their wide scale use in this area, the deluge valve systems can be referred to as being one of among the fire safety devices. They are an inherent part in the fire protection systems. The pipelines of the fixed fire protection systems mostly remain empty throughout the operation of a process but when suddenly a fire occurs then the deluge systems deliver enough water through the pipelines in order to extinguish the fire.

Deluge valve systems are quite popular to be used for a transformer system. They are also used for conveyor protection, storage tanks containing flammable substance, in aircrafts, any area where inflammable liquids are being used, they are also used to cool equipments in order to prevent structural collapses.

Working of Deluge Valve System

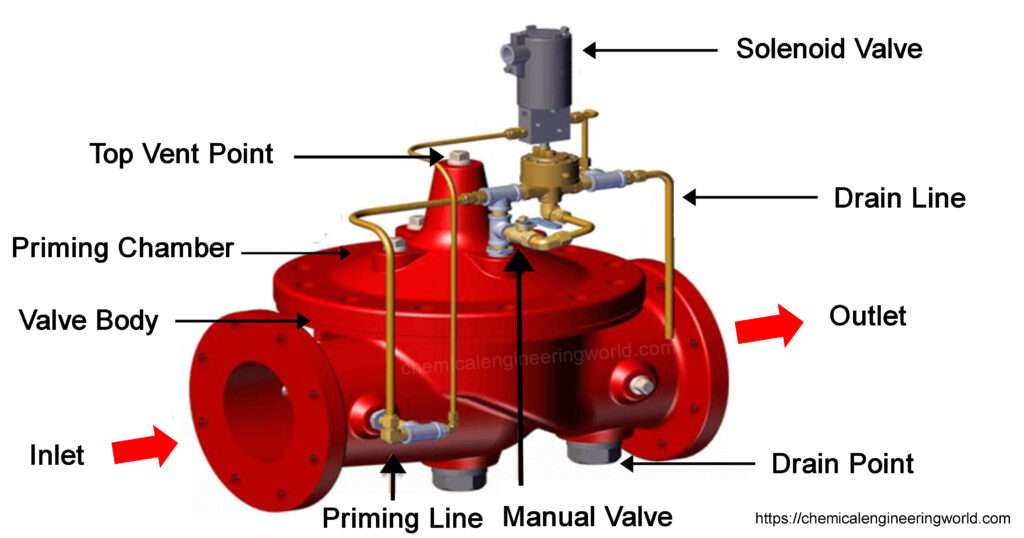

The deluge valve is actually a quick release diaphragm valve. It has three chambers. When the valve is in the set position, which means when it is not being used in the process, then there are three chambers isolated from each other. The clapper and seat seal which are operated via a diaphragm are able to produce the three isolated chambers when the device is not being used. When it is being used then the position of clapper and seat seal changes due to which two chambers join with each other. The third chamber is which helps in opening or closing the valve. The third chamber is also called as top or priming chamber. The rest of the chambers can be called as inlet or primary chamber and outlet chamber.

When the valve is in set position then there is a passage of water through the primary chamber but it doesn’t flow through the outlet chamber instead it bypasses to the priming chamber via a bypass line. When water flows in the priming chamber then it causes the chamber to expand as the chamber is supported by diaphragm operated clapper and seat seal. The pressure of the water from the primary chamber itself will help in keeping the device always in set position. The connection of the bypass line is opened or closed using a solenoid if the system is automatic or with a lever if the system is manual.

The system comprises of a detector or even a variety of detectors in order to detect the changes in temperature which happens due to increase in heat near the area or it can also detect the smoke or flame directly. The system contains a control panel. The control panel receives instructions from the detector and it accordingly instructs the solenoids to cause the water stored in the priming chamber to get released and thus the clapper and seat assembly moves upwards. It causes the water to move from the inlet chamber to outlet chamber and thus a large amount of water flows towards wherever it is needed at the moment. When the fire gets extinguished then the deluge valve system returns to its set position.

Advantages of Deluge Valve System

- It uses water for extinguishing fire. Water are easier to store and transport when compared to other fire extinguishing chemicals. Also they are relatively cheaper.

- The whole deluge system is comparatively less expensive than other systems of similar applications and also they are very fast in response.

Disadvantages of Deluge Valve System

- Since they immerse the area in large volume of water, if they do this to sensitive electronic equipment then it may get damaged.

- It requires a large reservoir of water to be connected at all times and that water cannot be used for any other purpose.

Reference:- instrumentationtools, processindustryforum