Flashback | Flame Arrestor Working and Types

Flashback | Flame Arrestor Working and Types

Flashback | Flame Arrestor Working and Types

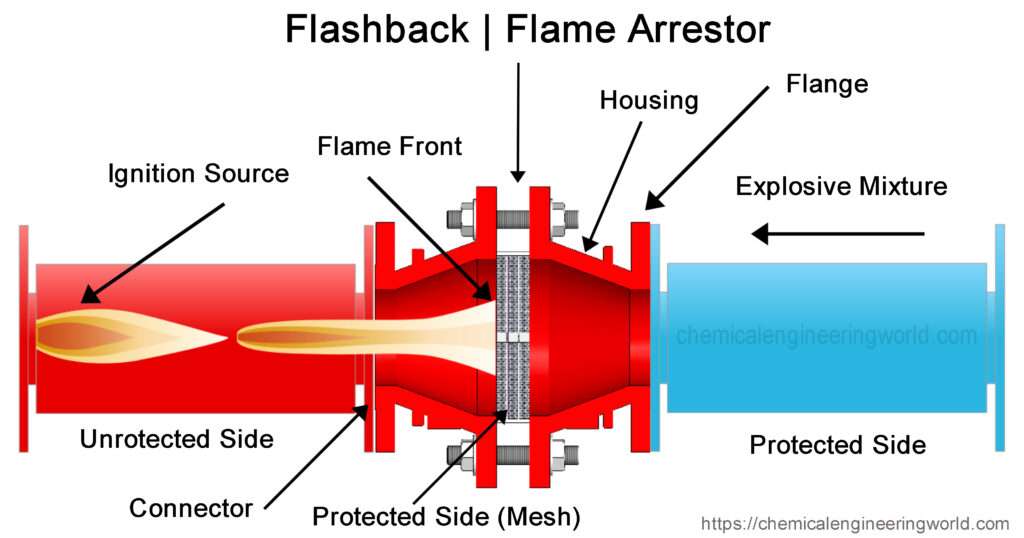

Flame arrestor is a safety device which is used to inhibit the flame propagating through equipment. The equipment which involves flammable vapours and gases or reactive gases is in potential danger to get burnt or exploded in case the vapours catch fire. The flame arrestor doesn’t let this happen; it prevents this situation from happening.

Some of the processes which involve flammable vapours or gases include Reacting, Mixing, Blending, Drilling and Separation. Some of the industries which use the processes and combustible vapours and gases are Chemical, Petrochemical, Refining, Oil Exploration, Sewage Treatment, Power Generation etc.

It is relatively simple equipment which contains no moving part, does not require a power supply and does not require an operator to observe it; it just requires maintenance over certain time periods. Some common objects which have flame arrestors are fuel gas pipelines and storage tank vents, the exhaust system of internal combustion engine, davy lamps in coal mining, gasoline containers, safety storage cabinets for volatile liquids having flammable vapours. The sizing of the flame arrestor depends on the area of application.

Principle of flame arrestor

The flame arrestor has high thermal conductivity elements which contain channels or passages which absorb the heat of the burning gas or vapour. The absorption of heat will cause the temperature of the burning gas or vapour to decrease and finally to reach a point where the temperature of the burning gas or vapour will drop below its autoignition temperature. When this happens the gas will stop burning unless and until a spark source is not reintroduced into the gas or vapour.

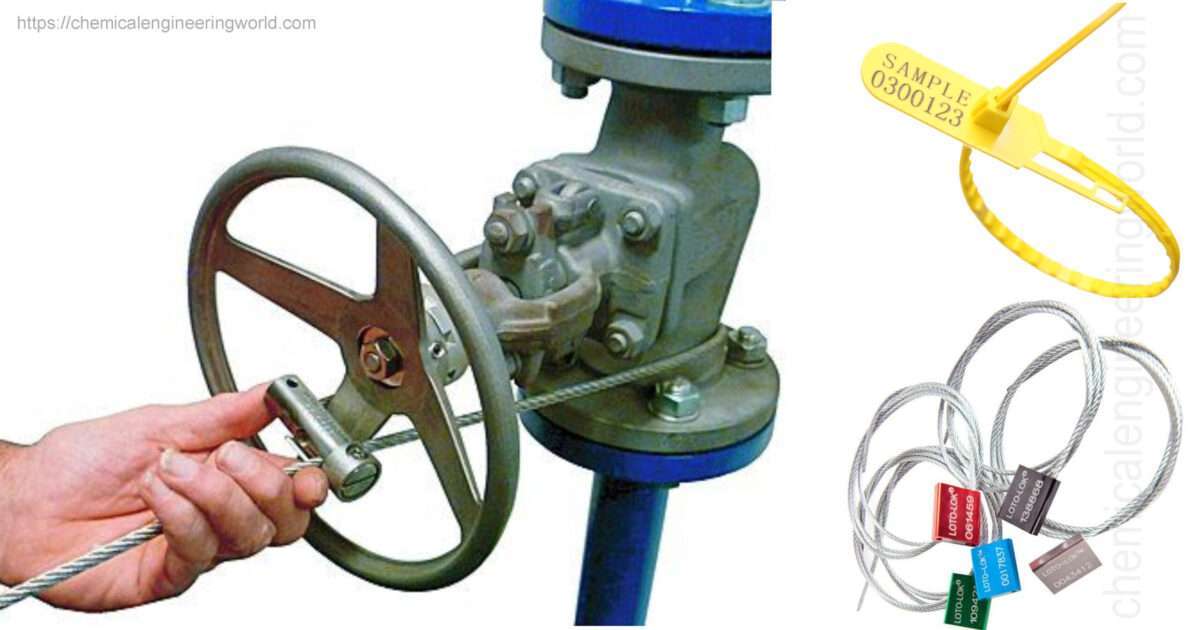

The channels are choses and measured in terms of Maximum Experimental Safe Gap (MESG) for a particular installation. There are a variety of designs for the channels which can be of the form of wire mesh, sheet metal plate, ribbon, crimped metal etc.

Uses of flame arrestor

- To prevent the gas or vapours from igniting.

- In case the gas or vapour ignites then to stop the propagation of flame.

- If it has propagated to some extent then confining the fire within a controlled region.

- If an explosion has occured then limiting the spread of the explosion.

- Stopping the spread of an open fire.

Types of flame arrestor

- End-of-line deflagration flame arrestor

- In-line deflagration type flame arrestor

- In-line detonation type flame arrestor

End-of-line deflagration flame arrestor:

Deflagration is defined as an explosion propagating at subsonic flame speed. They are used in areas where the potential ignition sources are located outside of the system. Many common designs contain a crimped metal ribbon which are used to inhibit the propagating flame. They are normally installed in atmospheric type storage tanks as well as other process vessels and also in transportation containers.

In-line deflagration type flame arrestor:

They are specifically designed in order to confine the propogating flame. The distance between the flame arrestor and the potential ignition source should be within the standard recommended pipe length to diameter ratio. The distance will be relatively smaller for those gases and vapours which burn really fast than those which burn relatively slow. For example the distance for applications using hydrocarbon-air mixture is greater than the distance between the applications using hydrogen-air mixture.

In-line detonation type flame arrestor:

Detonation is defined as an explosion propagating at supersonic flame speed. Usually deflagration transitions into detonation if the combusting fuel-oxidant mixture has travelled a certain distance in the pipeline. The detonation carries shockwave with it in front of the flame. Detonation is liable to cause relatively more damage than deflagration. Hence these types of flame arrestors are used when the distance between the potential ignition source and deflagration type flame arrestor is very large.

Reference:- piping-world, emersonautomationexperts, wikipedia