Gas Turbine Working and Types

Gas Turbine Working and Types

Gas Turbine Working and Types

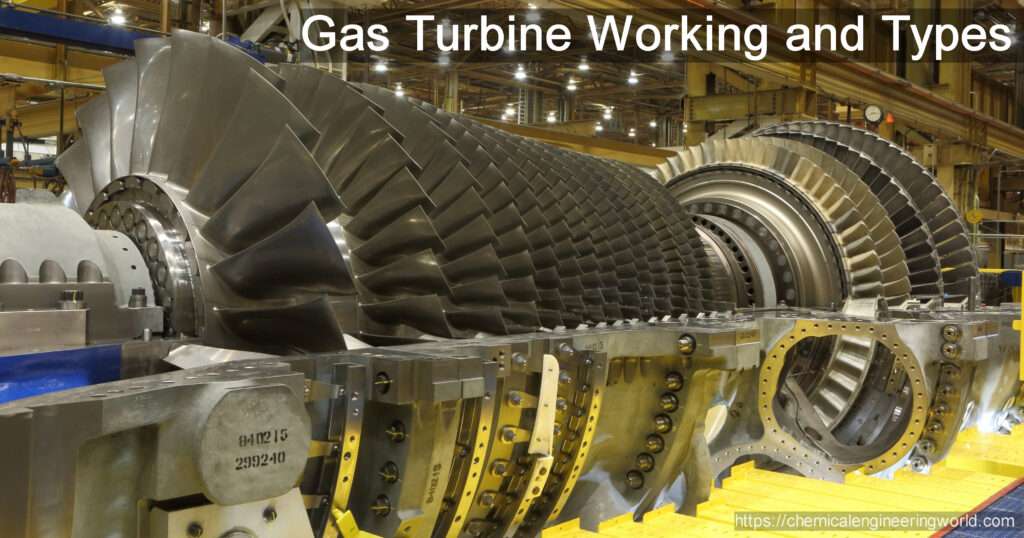

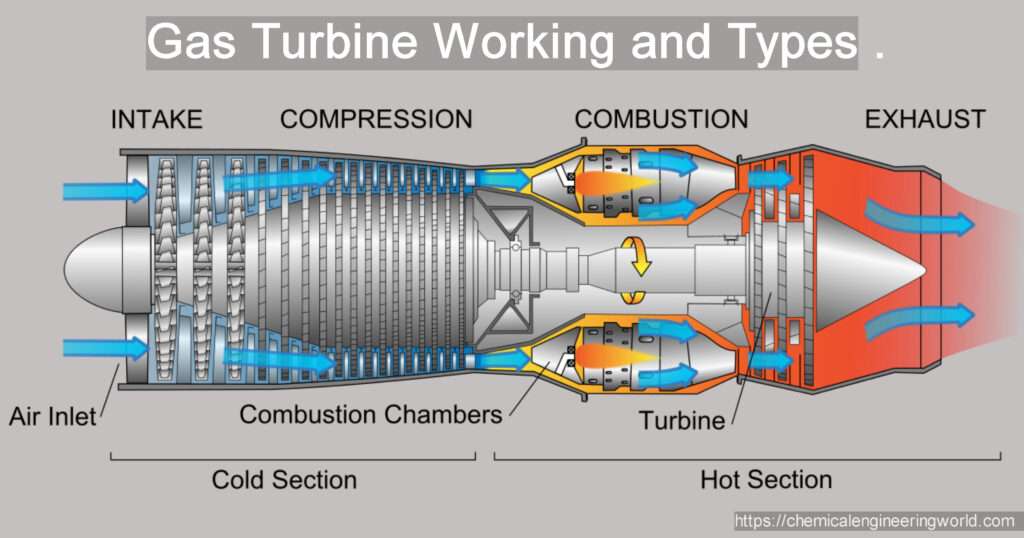

A gas turbine, in layman terms, is a type of internal combustion engine that converts chemical energy into mechanical energy. The main elements of a typical gas turbine are: 1. Gas compressor 2. Combustor 3. Turbine. The compressor, combustor, and turbine are called the core of the engine. These are usually mounted as an integral unit and operate as a complete prime mover on a so-called open cycle where air is drawn in from the atmosphere and the products of combustion are finally discharged again to the atmosphere.

Gas Turbine Working

The thermodynamic process used in the gas turbine is the Brayton cycle (with the exclusion of the fourth step). Air and fuel are the two main components that are required for the working of a gas turbine. Fuel is usually natural gas, but other liquid fuels are also in use. First, air is drawn in from one end of the turbine and passed through a compressor section.

As it is compressed, the temperature of the air rises and the pressure also increases. Next, fuel is injected into the turbine. Here it mixes with the compressed air and starts to burn. This is chemical energy. The air to gas ratio depends on various factors such as specific heating value of gas, moisture content and quality of air. The hot gas produced from the ignited mixture comes in contact with the turbine blades, causing it to spin at very high speeds (around 3200 rpm). Thus, chemical energy has been converted into mechanical energy. This is typically what happens in a jet engine.

Gas turbines are also widely used for electricity generation. They are an integral part of the combined cycle power plant, wherein, chemical energy is converted to mechanical energy and this mechanical energy is then converted into electrical energy. As explained before, the hot pressurized gas forces the blades to spin at high speeds. This causes the drive shaft to rotate. This rotational energy is then transferred to the shaft of the generator (an electrical machine) through a gearbox.

The generator has a large magnet that is surrounded by coils of copper wire. When that magnet starts to rotate at great speed, a powerful magnetic field is created which in turn causes the movement of electrons and thus electricity is produced. The excess energy produced in the turbine can be used to produce steam which in turn can be used to run a steam turbine. Thus, the use of both the steam and gas turbines together would help in generating more power efficiently.

Gas Turbine Types

- Turbojet

- Turboprop

- Turbofan

- Afterburning Turbojet

Turbojet:

The turbojet is the simplest of all turbine engines. A turbojet engine was first developed in Germany and England prior to World War II. These engines have limited range and endurance and also have high fuel consumption. In this type of engine, air is passed at a high rate of speed into the combustion chamber where the fuel inlet and igniters are located. The turbine, driven by expanding air, causes thrust from accelerated exhaust gases.

Turboprop:

The turboprop turbines are the most commonly used engines in small aircrafts, cargo planes and agricultural purposes, partly because of their superior fuel efficiency. They also have an optimum propeller performance at lower rpm speeds as these engines drive their propellers through a reduction gear.

Turbofan:

Turbofan combine the best features of both the turbojet and turboprop engines. In this engine, a secondary flow of air is diverted around the combustion chamber, therefore providing additional thrust. They are heavier than turbojets and is also quite inefficient at higher altitudes. Most the airlines operating today use the turbofan engines.

Afterburning Turbojet

As the name suggests, an afterburner is placed in the normal turbojet so as to use some of the energy from the exhaust stream to turn the turbine, thus generating additonal thrust.

Reference/Image:- aircraftsystemstech, britannica 3dprintingindustry, nasa