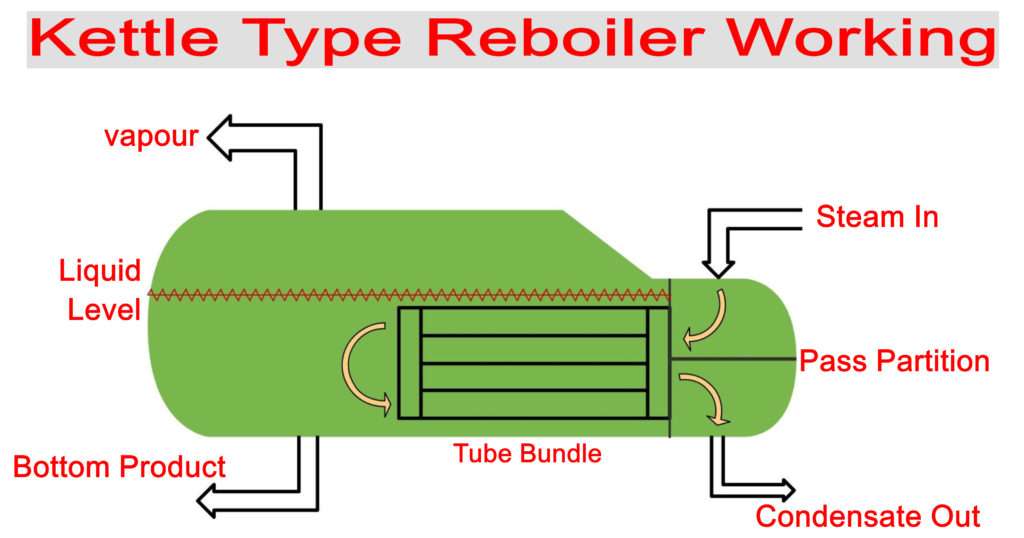

Kettle Type Reboiler Working

Kettle Type Reboiler Working:- A reboiler is an equipment which is installed with the distillation column and its purpose is to convert the liquid which is provided by the bottom tray of the distillation column into vapours. These vapours are then returned to the distillation column. A reboiler is essentially a heat exchanger

Kettle type reboiler is one of the most common types of reboiler used in industries.

It consists of tube bundles, the tube bundles are supported by a support plates. The structure of tubes can be either straight tubes or U-shaped tubes. The straight tubes are more versatile they make the cleaning easier. The U-shaped tubes have an advantage that they allow for thermal expansion without putting the rest of the exchanger at risk.

The defining feature of the Kettle type reboiler is that the tube bundles are placed inside a large specifically designed horizontal shell known as TEMA K-shell. The weir is provided inside the shell in order to control the level of the liquid. The vertical length of the weir dictates what quantity of liquid will be retained in the shell. It is important because the tube bundle must compulsorily be immersed inside this quantity of liquid at all times during the runtime of the process.

Working of Kettle type reboiler

The liquid to be vaporized is made to sump through the shell side, usually by the effect of gravity or if sufficient head is maintained in the column.. The liquid is made to cover the tube bundle entirely. This liquid is commonly called Bottoms in the distillation process.

Steam is made to flow through the tube bundles, pass partitions are provided in order to get highly effective heat transfer relative to single pass.

The latent energy of steam is utilized in vaporizing the bottoms liquids. The Kshell has enough space so that the separation of vapour and liquid takes place inside the shell itself. The vapour rises and is directed inside the distillation column and flows overhead inside the column.

The liquid which crosses the weir is removed from the reboiler and it is called Bottoms Product. Due to the boiling process the amount and constituency of more volatile components is reduced in the Bottoms product.

Advantages of Kettle type reboiler

- Low circulation rates, horizontal configuration and all vapour return flow make kettle type reboiler relatively insensitive to system hydraulics, as a result they tend to be reliable even at very low (vacuum) or high (near critical) pressures.

- Kettle type reboilers can operate efficiently with small temperature driving forces, as high heat fluxes can be obtained by increasing the tube pitch.

Disadvantages of Kettle type reboiler

- Oversized TEMA K-shell is relatively expensive.

- Low circulation rates make kettles very susceptible to fouling