Types of Compressors

Types of Compressors:- Compressors are mechanical devices whose purpose is to pressurize gases just as Pumps are used to pressurize liquids and transport them through pipes. Since gases are compressible in nature, the effect of the compressor is also that the volume of the gases gets reduced.

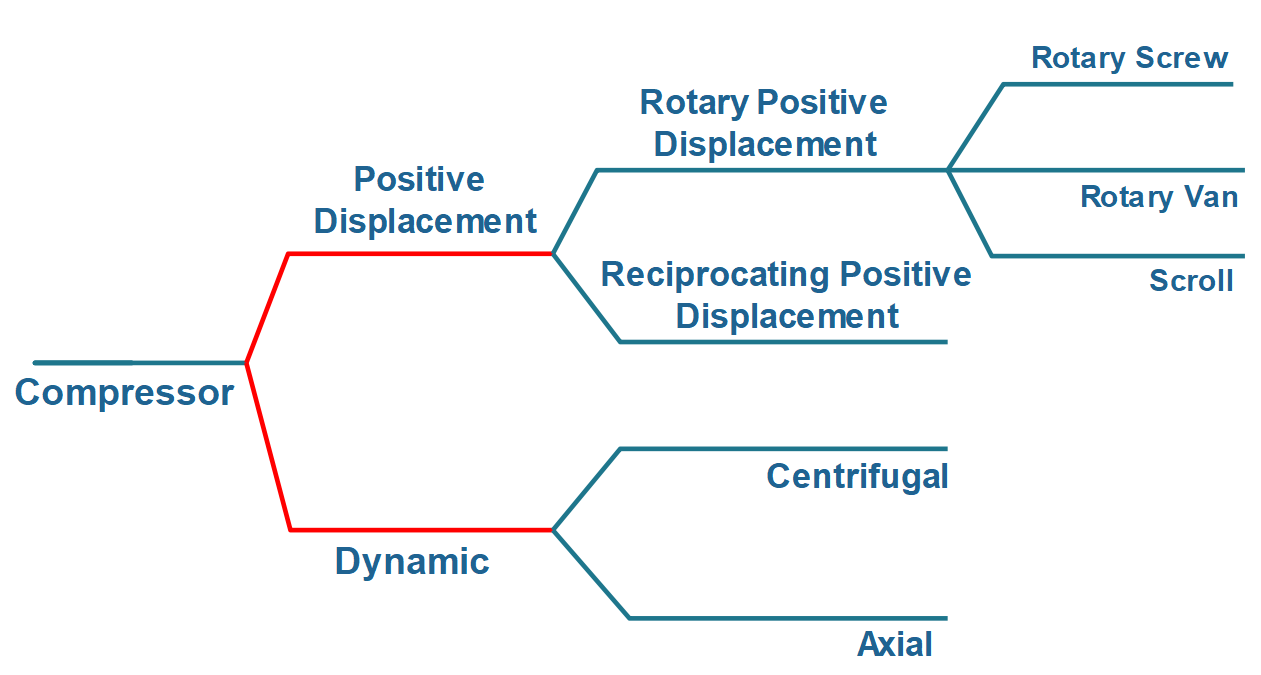

The compressors are divided into two classes; those belonging to Positive displacement type and those belonging to Dynamic type.

1. Positive Displacement Compressors

Positive displacement compressors have mechanical parts which draw in gas in steps of discrete volume from the inlet of the compressor. This action reduces the volume of the gas, increases the pressure of the gas and discharges the gas from the outlet of the compressor.

Positive displacement compressors are divided into two types; Rotary type and Reciprocating type.

A. Rotary Positive Displacement Compressors

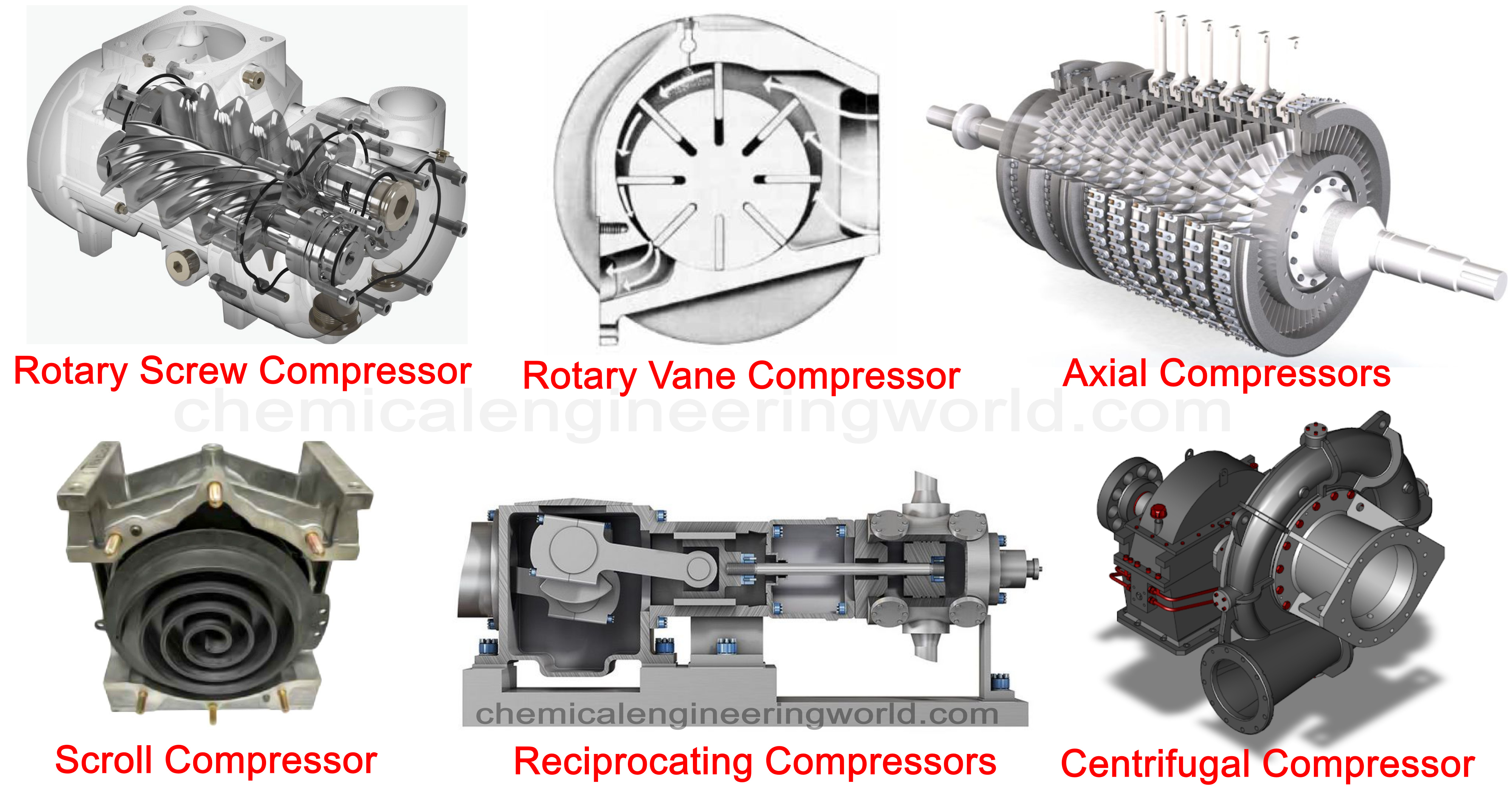

As the name indicates, Rotary types of positive displacement compressors contain some rotating mechanism which helps to draw in the gas and also to discharge it. Some examples of Rotary type of compressors are Rotary Screw Compressor, Rotary Vane Compressor and Scroll Compressor.

Rotary Screw Compressor

Screw compressors contain a pair of helical screws called a male screw and female screw. The rotating motions of the screws are responsible for drawing in gases from the input of the compressor. The gas is drawn in continuous sweeping motion. They don’t make much noise when they operate and the compressor does not vibrate much during the run time.

Rotary Vane Compressor

Rotary Vane compressor consists of a rotor mounted with vanes. The vanes extend and touch the walls of the housing creating a condition in which the gas will not be able to leak through the clearance between the wall and the edges of the vanes. The rotating motion causes the volume of the gas to increase and decrease thus moving through the compressor.

Scroll Compressor

The rotating mechanisms in the scroll compressor are pair of interleaved spiral like vanes. Often one of the scrolls is fixed and the other scroll operates eccentrically. This movement draws in and compresses gases. They are one of the quietist compressors in operation. The very small clearance between the fixed scrolls leads to high volumetric efficiency.

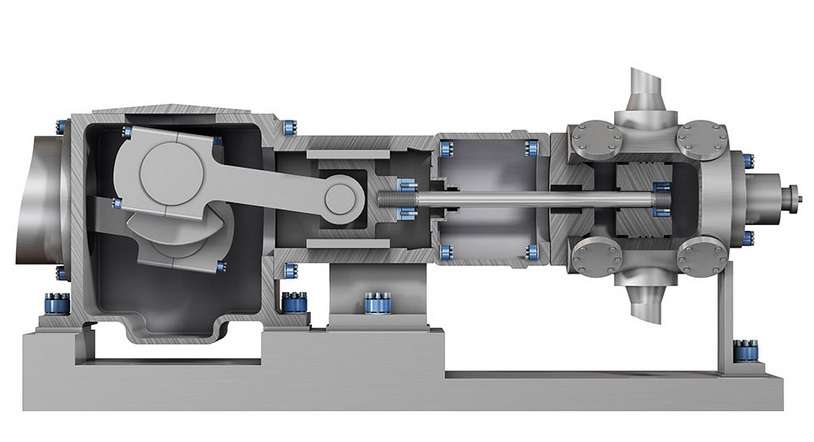

B. Reciprocating Positive Displacement Compressors

Reciprocating positive displacement compressors contain an assembly of piston and crankshaft. The purpose of the assembly is that when the gas is sucked inside the compressor the crankshaft mechanism will produce a reciprocating motion and will move the piston in order to compress the gas.

Based on the manner in which the cylinder inside the compressor motor reacts with the working fluid; the reciprocating compressors can be Single Acting or Double Acting.

In the single acting mechanism the gas interacts with the cylinder only once during the up-stroke of the piston. In double acting mechanism the gas interacts with the cylinder twice, it means the gas is compressed twice; during the up-stroke and the down-stroke of the piston.

2. Dynamic Compressors

The defining feature of the Dynamic Compressors is that they contain rapidly rotating blades. The movement of these rapidly rotating blades draw in gases and compresses them inside the compressor. Dynamic compressors are generally used for large scale operations. Types of dynamic compressors are Centrifugal Compressors and Axial Compressors.

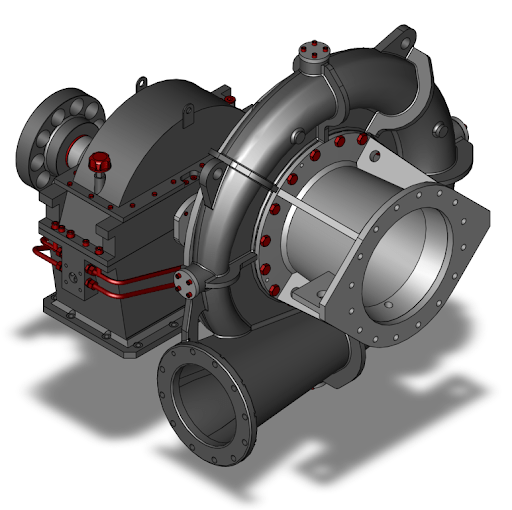

A. Centrifugal Compressor

Centrifugal compressors contain impeller. The impeller rotating at very high speed sucks in gas and accelerates it to such high velocities that in some cases the velocity of the moving gas reaches the speed of the sound. Before such high velocity gas is discharged it is passed through a section of increased area. This causes the kinetic energy of the moving gas to get converted into static energy.

B. Axial Compressors

Axial compressors contain a set of airfoils which are stacked in a row. Usually one air foil rotates and the airfoil next to it remains stationary. The rotating movement of the airfoils progressively compress the gas. They are able to achieve high flow rates in compact design, due to this feature they turn out to be quite expensive.