Unit Operation and Unit Process

Unit Operation and Unit Process :- The entire chemical engineering can be classified into two groups; unit operations or unit processes. The concept of unit operations was introduced in 1915 by Dr. Arthur D. Little. The concept of unit processes was introduced in 1923 by P.H. Groggin.

Unit Operations

A unit operation is defined as a process which does not involve any chemical reaction. Unit operations only deal with physical changes of the materials involved in the process. They are equipments which cause the materials to undergo physical changes.

The physical changes are carried out for variety of purposes. Generally unit operations steps are carried out before subjecting the materials to chemical reactions so that chemical reactions happen smoothly.

The physical changes can imply phase changes such as; evaporation, condensation, crystallization etc. Thus Distillation is a unit operation step because condensation and evaporation happens inside the column. Evaporators, and crystallisers are also unit operations equipment.

Unit operation equipments are also responsible for mechanical operations which involves size reduction, physical separations, mixing, and grinding. The mass transfer, heat transfer process all may happen together. Chemical reaction doesn’t happen.

The unit operations are classified in the following manner:

- Fluid flow operations: Pumping, compression, and fluidisation.

- Mechanical operations: Size reduction, size enlargement, mixing, agitation, blending, filtration, classification-separation, etc.

- Mass transfer: Distillation, evaporation, crystallization, leaching, absorption, adsorption, extraction, etc.

Heat transfer: When materials are handled the heat transfer can take place by any fundamental mechanism; conduction, convection, or radiation. Usually two fundamental mechanisms occur simultaneously.

Unit Process

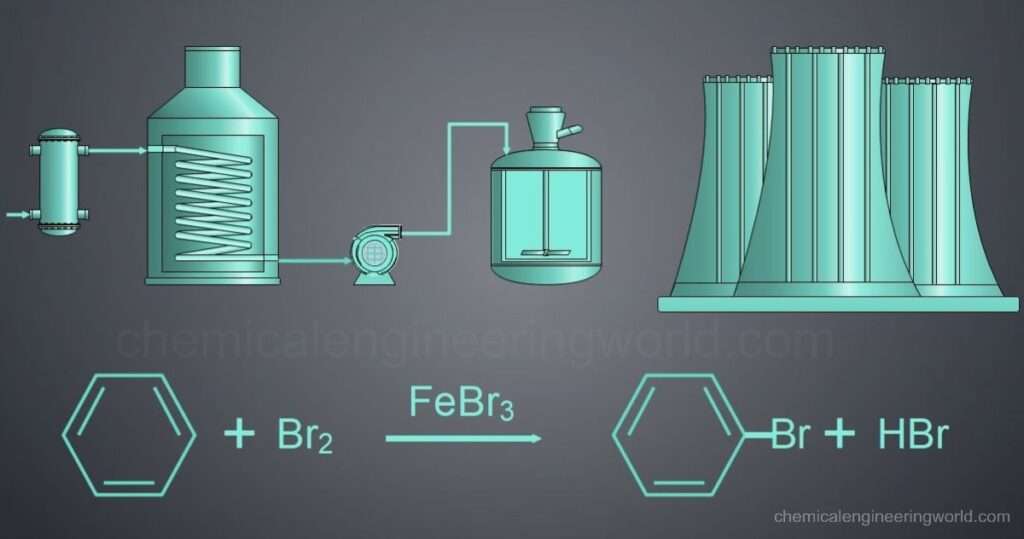

Chemical reaction is at the heart of the unit processes. A chemical reactor is an equipment which falls under the category of unit processes. Literal chemical change takes place inside the equipment wherein the the chemical structure of the material changes and it transforms and forms an entirely new material.

All kinds of chemical reactions carried out in industrial equipments comes under this category. Some examples of such chemical reactions are; sulphonation, nitration, halogenation, alkylation, hydrolysis, hydrogenation, polymerization, oxidation, reduction, etc. The examples can be innumerable as there can be innumerable compounds which can be formed by reaction of two or more materials or by decomposition of the material itself. Thus classification can be similarly endless.

Most of the chemical reactions are irreversible in nature. A chemical reaction step in a process forms the heart of the process, often governing the economics of the entire process. Thus the unit processes are often subject of optimization.

Often unit operations have to be carried out before unit processes to give proper shape to the materials so that they will be able to react optimally. Also unit operations are often needed even after the chemical reaction has happened, they are needed for the purpose of separation of the primary product from the secondary or tertiary products. All the unit operation processes wherein chemical reaction is made to take place to improve the efficiency of the equipment also falls under unit processes. For example, reactive distillation, reactive extraction, reactive absorption, etc.

Reference:- Chemical Tweak