Block and Bleed Valve Function

Block and Bleed Valve Function

Block and Bleed Valve Function

In the chemical plant, we need to isolate certain equipment frequently for cleaning, maintenance, and repair. We need to perfectly isolate the equipment because fluids are very flammable or toxic so leakage of fluid can cause a huge problem. For isolating a certain mechanism is available which is called Block and Bleed valve. Block and bleed is nothing but a combination of one or two block valves and one bleed valve.

To repair or clean one component of the plant we can’t afford to shut down the whole plant and then work on it for that we use a block and bleed system which will depressurize the system and isolate a particular section and then we can work on it without interfering whole process plant. This is why the block and bleed system is very useful.

Types of Block and Bleed valve

- Single block and bleed valve

- Double block and bleed valve

- Single unit Double block and bleed valve

1. Single block and bleed valve

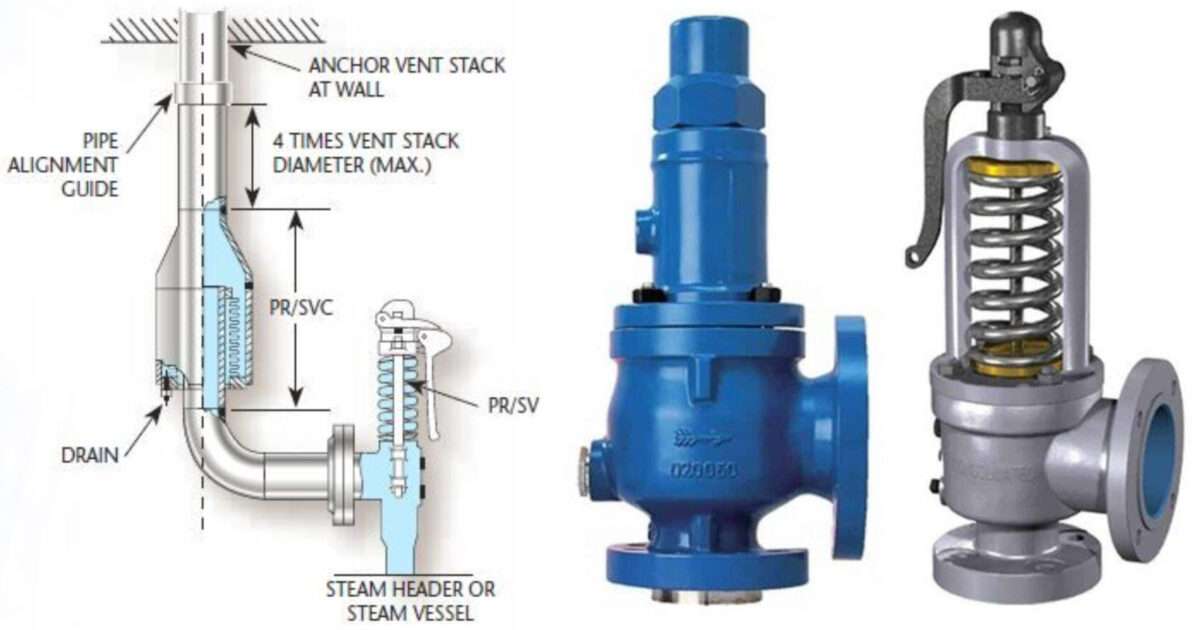

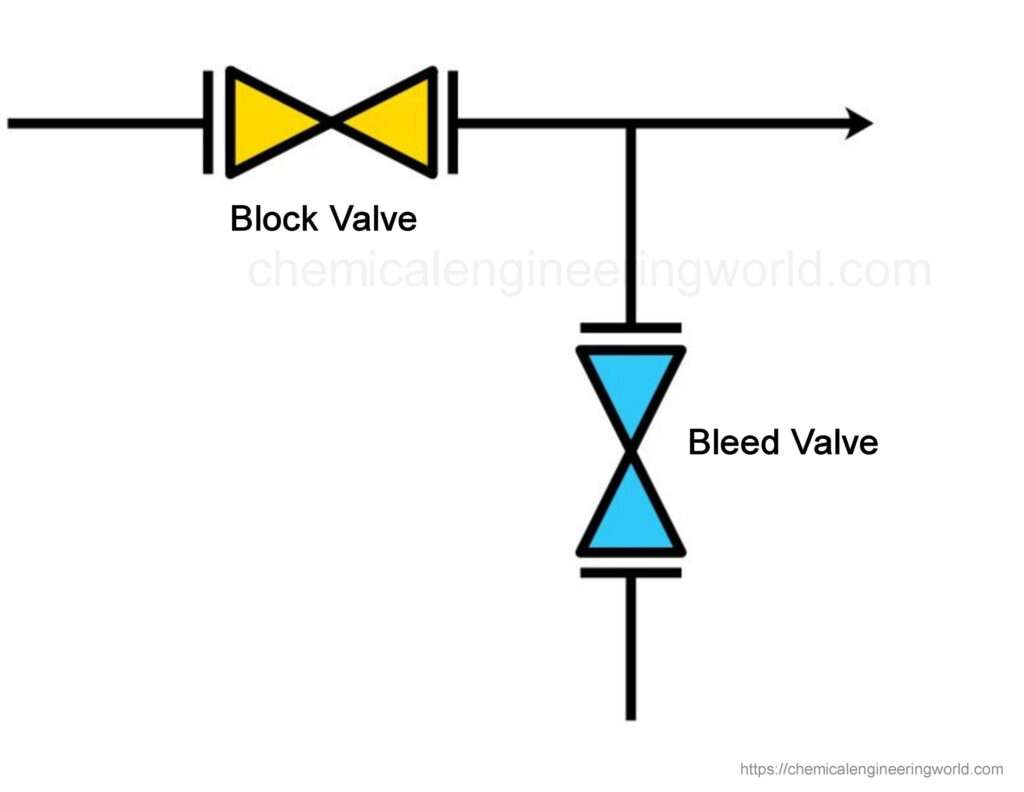

The single block and bleed valve system consists of one block valve and one bleed valve. A single block and bleed valve is used in processes that are not much critical like a low-pressure system. When the process fluid is not flammable or toxic we can use a single block and bleed valve system. Here we have one block valve which is usually a ball valve and one bleed valve which is usually a needle valve. Whenever we want to isolate some equipment we need to block process fluid flow by closing the block valve and after that, we need to open the bleed valve to vent or remove extra process fluid in between equipment and block valve. This is how a single block and bleed valve works.

2. Double block and bleed valve

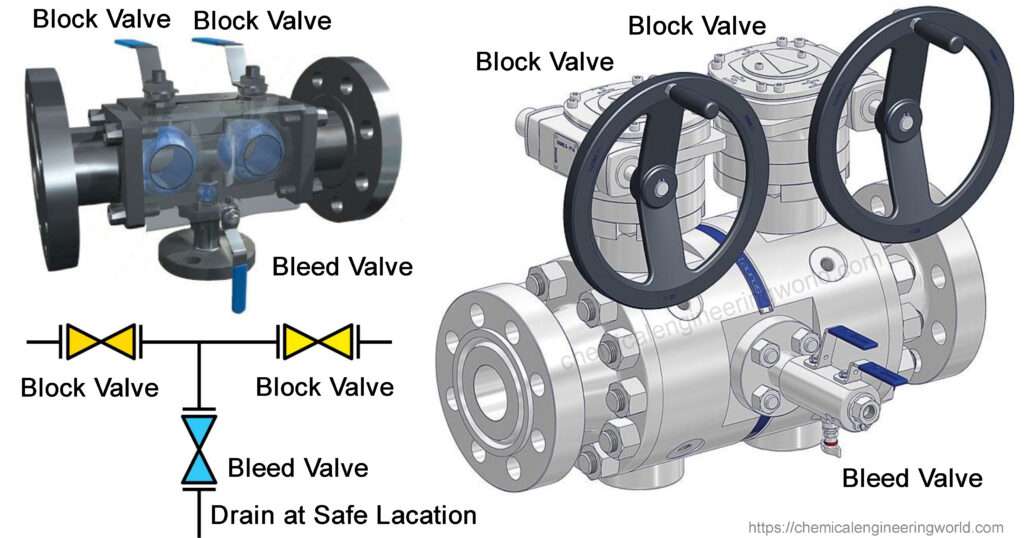

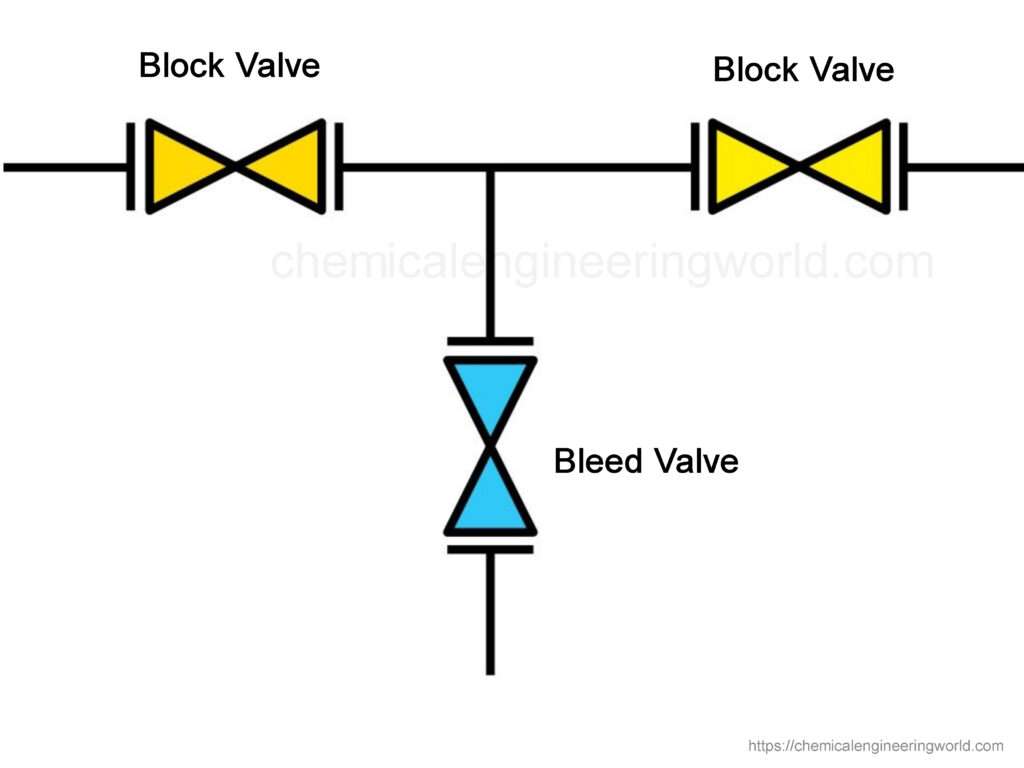

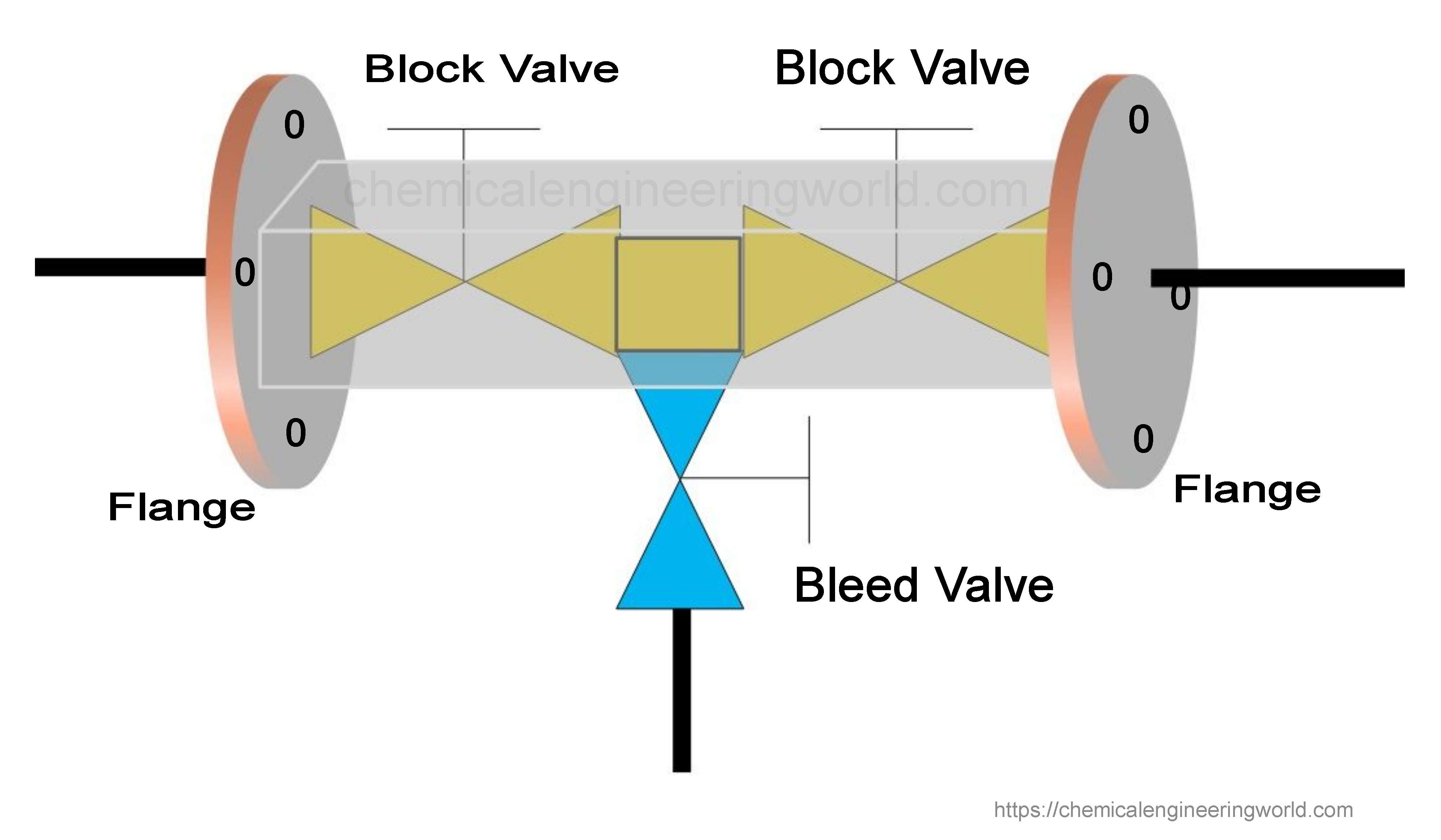

It is consists of two separate block vales and one bleed valve between them which drains liquid. it has three valves.

API 6D definition of double block and bleed valve, “Single valve with two seating surfaces that, in the closed position, provides a seal against pressure from both ends of the valve with a means of venting/bleeding the cavity between the seating surfaces.”

OSHA definition of double block and bleed valve, “The closure of a line, duct or pipe by closing and locking or tagging two inline valves and by opening and locking or tagging a drain or vent valve in the line between the two closed valves.”

3. Single unit Double block and bleed valve

Here, we have three valves two block valves, and one bleed valve in a single unit which has many advantages like saves space, less weight, and ease of operation. It isolates the system better than other options. It isolates the system from both the sides upstream and downstream. The valve between the two block valve is called a bleed valve. After isolation bleed valve will drain fluid from the cavity between two block valves.

Applications of Block and Bleed valves

- To isolate particular equipment or pipe for maintenance

- Used in oil and gas industries

- Meter calibration

- Remove equipment for cleaning

Advantages of single unit double block and bleed valve

- Ensures safety while cleaning or maintaining any equipment

- Zero leakage

- Require less space

- Ease of operation

- Easy to install

Block and Bleed Valve Function Video

Reference:- enggcyclopedia, theprocesspiping Image:- as-schneider, wermac