Heat Tracing on Pipeline

Heat Tracing on Pipeline

Heat Tracing on Pipeline

Heat tracing is a system consisting of a set of paths that is in physical contact with the pipe or vessel. They consist of a resistive element that heats up when electricity is made to pass through it. Oil and gas industries make use of heat tracing systems on a wide scale.

The main application of a heat tracing system is to maintain the temperature at the desired level. Heat losses may occur as a result of the pipe being at a higher temperature than that of the surroundings. Even if the pipes are provided with insulation, it still cannot hold in all of the heat that is produced. Thus, when the temperature goes below a desired value or the set point value, electricity is provided to the element, causing it to heat up and thus raise the system to the set point temperature. Steam also can be provided as an alternative to electric heating but it may not be convenient in many environments to provide steam and might also not be economically feasible.

Another application of heat tracing is in the prevention of freezing of pipes. In many cold countries, these pipes run the risk of being frozen out because of the extreme ambient temperatures prevailing. Also, heat tracing is used to melt the ice that is present on the roofs of houses and other building structures. Modern day heat tracing elements are present in the form of a cable. In the case of freeze prevention, this cable is placed in direct contact with the cold outside environment. The cable senses the temperature and heats up accordingly, melting the snow or ice surrounding it and therefore protecting pipe/roof from damage. It also helps to prevent cavitation while pumping highly viscous liquids. The viscosity of thick liquids decreases when their temperature is increased. Thus, it helps in smoother movement and helps prevent losses.

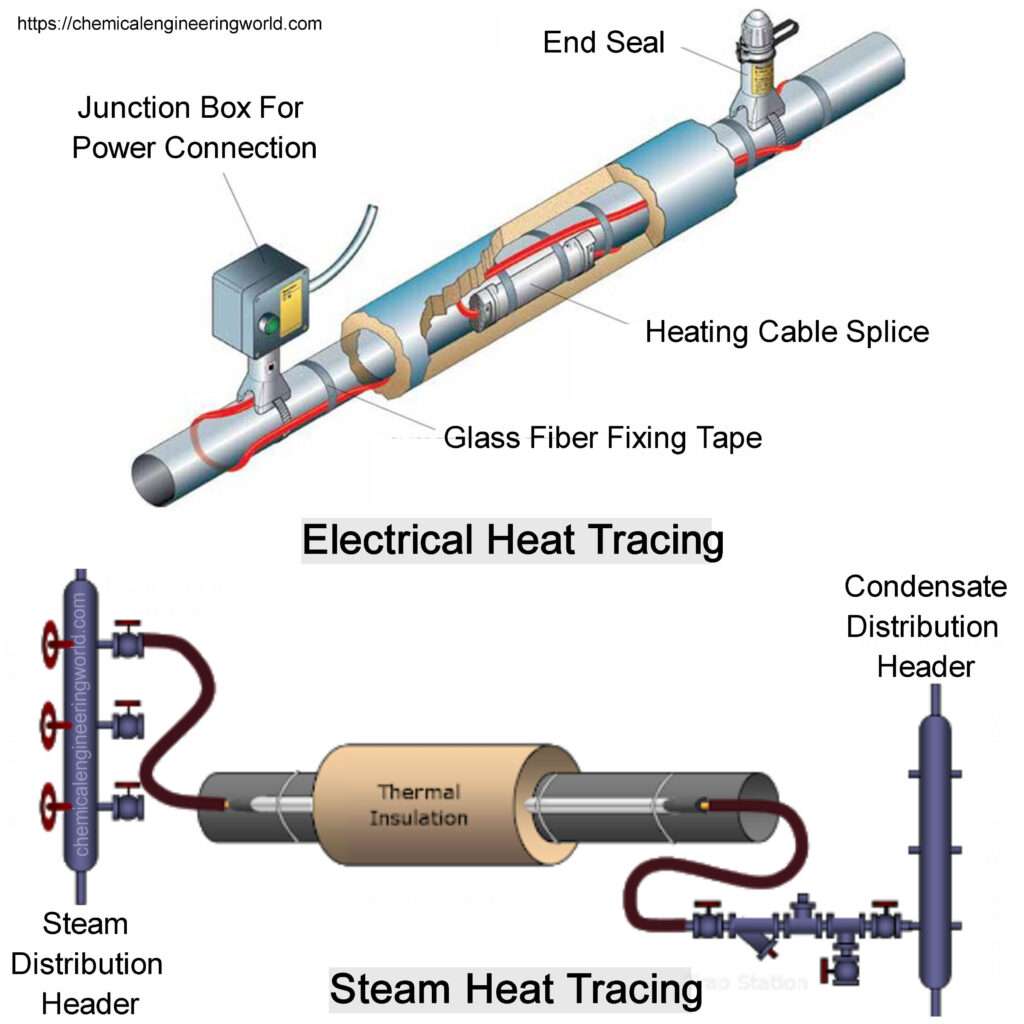

The first classification of heat tracing, as mentioned above, is on the basis of the kind of heat input provided. Heat can be supplied in the form of (i) electrical energy or (ii) in the form of a fluid. In the case of electric heat tracing, electric power is converted to heat and this heat is then supplied to the pipe that is to be traced. In the case of fluid heat trace, the fluid can either be steam or an organic heat-transfer fluid. Provisions for recycle and reheating has to be ensured if an organic fluid is being used.

The use of steam for heat trace is declining due to the high cost of installation and maintenance involved. Electric resistive elements are the most commonly used nowadays. Another classification is on the basis of how the heat input is provided: (i) constant electric power series and (ii) constant wattage systems. The series heating cable is provided as a continuous unit and when supplied with a high voltage, the resistive element generates heat. It is useful for maintaining high temperatures across pipelines but if shorting happens somewhere in between, the entire cable seizes to work as it is a continuous unit. On the other hand, the constant wattage cable is divided into multiple power zones. Therefore, even if one element stops functioning, it does not affect the rest of the cable and only that damaged element needs to be replaced.

Image Source:- indiamart