Types of Reactors

Types of Reactors:- A chemical reactor is a process equipment where in chemicals are fed in order to make them chemically react with each other for the purpose of making a desired product. Chemical reactors are designed in such a way to increase the net present value for a given reaction and it is done by ensuring highest efficiency to output the desired product.

Types of Reactors

- Batch Reactor

- Continuous Stirred Tank Reactor (C.S.T.R)

- Plug Flow Reactor (P.F.R)

- Semi-Batch Reactor

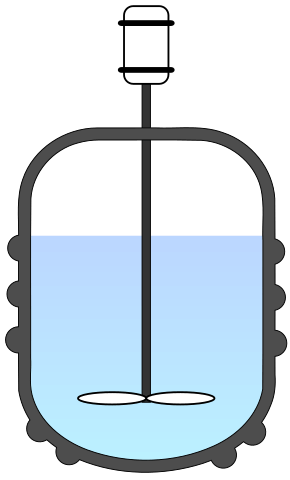

1. Batch Reactor

A batch reactor is a closed vessel in which reactions happen and it is a non-continuous type of reactor. The reactants are fed in to the reactor all at once initially. The vessel contains an agitator. The purpose of the agitator is to mix the reactants thoroughly so that the contact makes them react together efficiently and produce products.

In order to handle exothermic reactions the batch reactor is often equipped with cooling coils. In order to work with endothermic reactions the batch reactor has provisions for heating the reaction mixture.

The batch reactor is a non-steady, transient reactor. It means the extent of conversion within the reactor depends on time. Due to agitator the batch reactor is highly uniform in nature. It means the extent of conversion does not depend on location within the reactor. At a given time the extent of reaction at any location of the volume of the reactor will be equal to each other.

Advantage

The greatest advantage of operating a batch reactor is its versatility. Same batch reactor can be used to chemically react quite different variety of reactants. Batch reactors are especially used in cases where the reaction produces lots of products. Batch reactors are often used in labs to study kinetics of the liquid phase reaction systems.

Disadvantage

The disadvantage of batch reactor is that it requires lots of labour force to constantly charge reactants, discharge products and then to clean the reactor for the next batch.

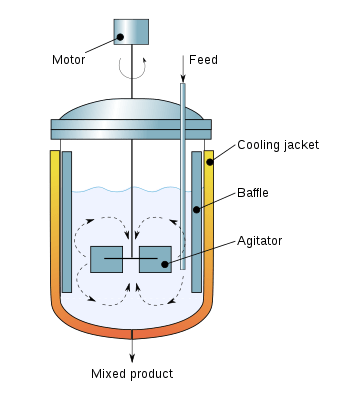

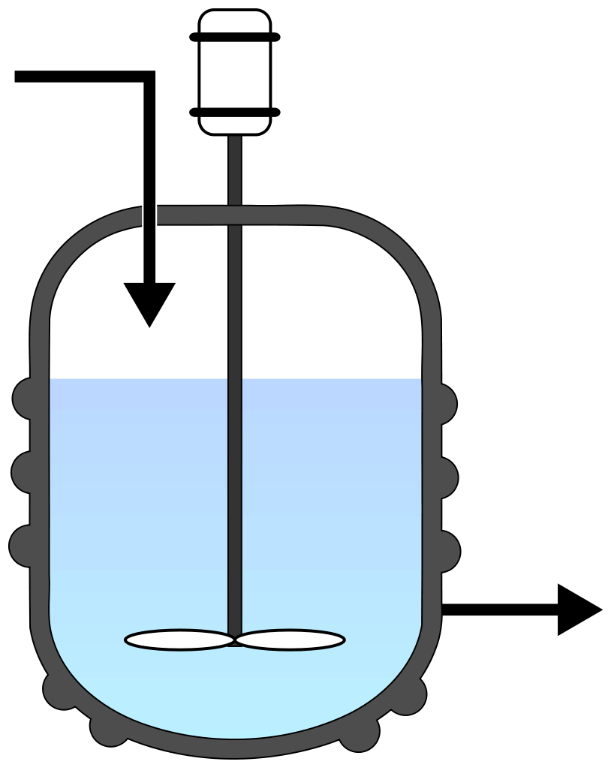

2. Continuous Stirred Tank Reactor (C.S.T.R)

A continuous stirred tank reactor (C.S.T.R) is also often called a mixed flow reactor (M.F.R). In this reactor also the reaction occurs in a closed tank. The tank also has agitator in order to mix the reactants thoroughly. It is different from batch reactor in the sense that the name itself indicates it is continuous type of equipment.

The reactants enter the reactor at a certain mass flow rate, the react inside the vessel for sometime dictated by the space time of the reactor and then they form products. The products flow out of the reactor at the same mass flow rate. One space time is the time required to process one reactor volume.

The C.S.T.R is steady sate equipment. It means the extent of conversion does not depend on the time. The agitator makes the concentration uniform throughout the reactor. It means the extent of conversion does not depend on the location also. The extent of conversion depends on the volume of the reactor.

Advantage

The biggest advantage of using a C.S.T.R in industries is that it can produce a large amount of products and being a continuous steady state reactor the reactor can keep on operating hours on end.

Disadvantage

The disadvantage is that a C.S.T.R cannot be used for reactions which have very slow kinetics because it will require a reactor of very large volume. The fabrication and operational cost of the reactor may make it infeasible. Batch reactor is used in this case.

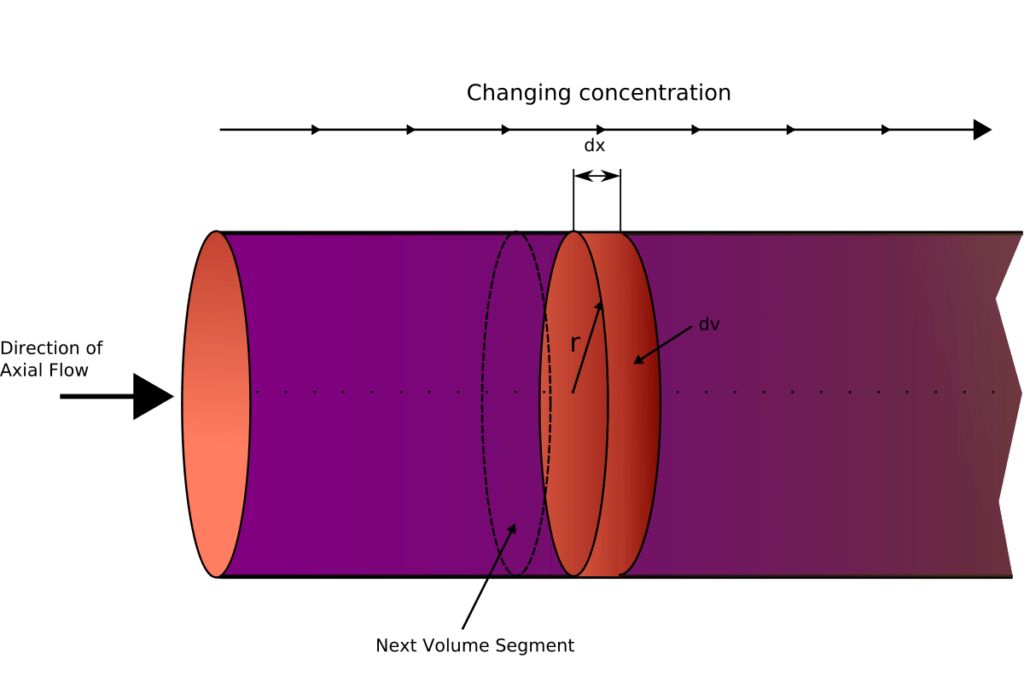

3. Plug Flow Reactor (P.F.R)

A plug flow reactor (P.F.R) is also sometime called a continuous tubular reactor (C.T.R). In an idealised model, the profile of the reaction mixture can be considered to be made up of a number of plugs and each plug having a uniform concentration.

The idealized P.F.R model has an assumption that there is no axial mixing. It means that there is no back mixing inside the reactor.

Advantage

The advantage of P.F.R over C.S.T.R is that for same space time and same level of conversion, the volume of the P.F.R is relatively smaller than a C.S.T.R, It means a smaller space is needed for the reactor also for same volume of reactor the level of conversion is higher in P.F.R than in C.S.T.R. Often the P.F.R are used to study kinetics of gas phase catalytic reactions.

Disadvantage

The disadvantage is that if we carry out an exothermic reaction in a P.F.R then the temperature gradients are difficult to control. The operational and maintenance cost of a P.F.R are also greater than a C.S.T.R.

4. Semi-Batch Reactor

A semi-batch reactor is a semi-flow reactor. It is a modification of batch reactor. It is also a closed vessel which contains agitator for the purpose of mixing the reactants thoroughly. The difference is that one of the reactants is charged completely initially in the reactor and the other reactant is charged continuously in the reactor as the time progresses.

Advantage

The advantage of using a semi-batch reactor is that if we are carrying out multiple reactions then we have a greater control over yield or selectivity of the products. This reactor is extremely useful when we are carrying out an exothermic reaction as the continuous flow of the other reactant can be varied to better control the exothermic reaction

Disadvantage

If we want to scale up the semi-batch process then disadvantage over the continuous process reactors (C.S.T.R and P.F.R) is that capital costs per unit scales up relatively a lot. Greater man power is required to charge and discharge the contents of the reactor, to clean blades, to clean reactors etc.