Venturimeter Working Principle

venturimeter working principle:- Venturimeter is an instrument which is used to measure average velocity of a flowing fluid or flow rate of a flowing fluid.

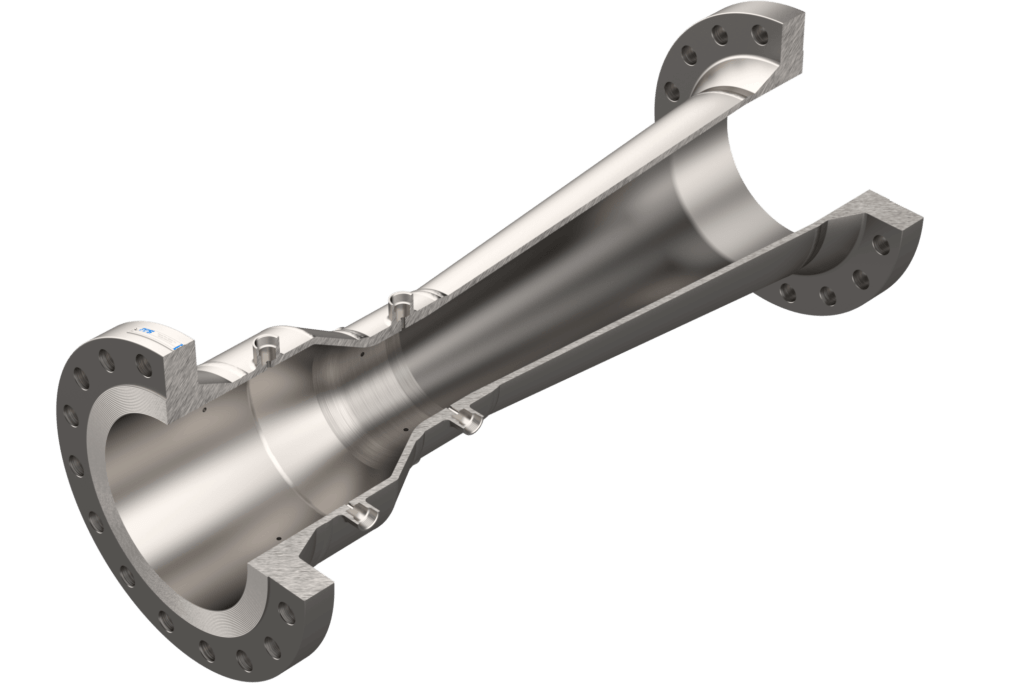

The venturimeter is attached to a pipe using flanges so that the fluid which is flowing through the pipe also flows through a venturimeter.

Working of the Venturimeter

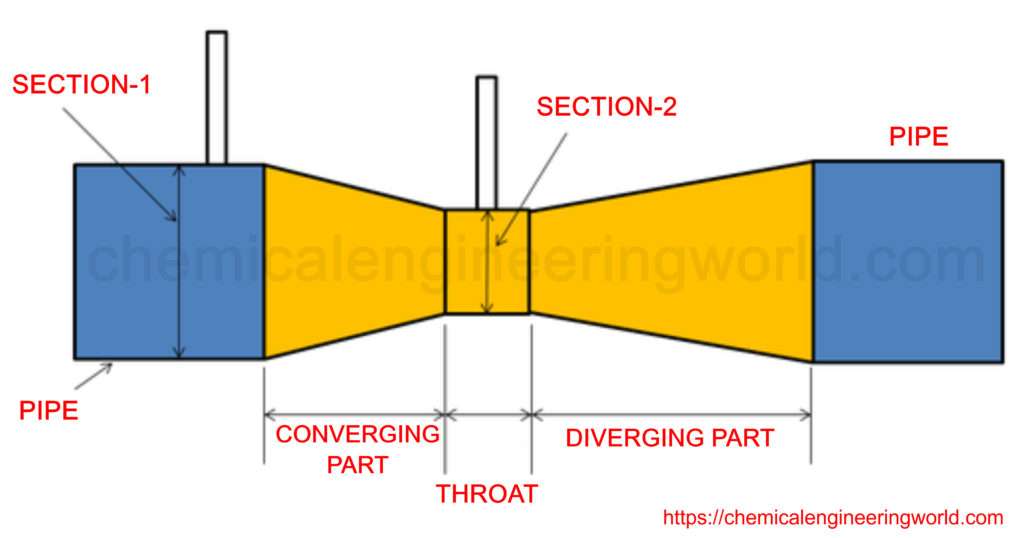

A venturimeter is a device which contains no moving part and it is made up of three parts:

The Converging part:

The fluid enters this part and due to the shape of the part, it starts to converge. According to the continuity equation, if the cross sectional area decreases then the velocity of the fluid increases. According to the Bernoulli’s equation, if the velocity of the fluid increases then the pressure has to decrease.

The Throat

The fluid then enters a part of constant diameter. This is called the throat. Since the diameter is constant the velocity of the flowing fluid does not change and also the pressure does not change in the throat. Hence, Throat is an apt place to apply pressure tapping. The pressure taping in the upstream position is applied before the fluid reaches the convergent section. The difference in pressures between these two positions is measured using a manometer or a pressure gauge.

The Diverging part

After the fluid crosses the throat, it passes through a diverging part. The purpose of the diverging part is to recover the pressure which was lowered in order to measure the flow rate. The angle of the diverging part is shorter than the converging part, this makes the length of diverging part relatively longer than the converging part. This is done purposefully so that the fluid doesn’t separate at the boundary, flow separation leads to pressure losses.

Principle behind the Venturimeter

Bernoulli’s principle states that; for a flowing fluid, an increase in speed of the fluid occurs with a decrease in pressure or a decrease in fluid’s potential energy.

It means if we know the extent by which the pressure has decreased, then we can find the measure by which the speed of the fluid has increased because they are related by the Bernoulli’s equation.

Bernoulli’s Equation Statement is given by:

Where, subscripts 1 and 2 indicate location of chosen points or sections in a flow field. P is pressure, ρ is density of the fluid, g is acceleration due to gravity, h is height of the point with respect to a reference line, v is the velocity of the flowing fluid.

In the schematic of the venturimeter, let the center line be the reference line then h for section 1 and 2 becomes zero. The Bernoulli’s equation for this case is written as:

The equation of continuity is given by:

Substituting this expression of velocity in the Bernoulli’s equation for the system and rearranging it, we get:

This equation gives the average velocity of the flowing fluid. If we multiply this velocity with cross sectional area then we will get volumetric flow rate. If we multiply the volumetric flow rate with density then we will get mass flow rate of the flowing fluid.