Heat Recovery Steam Generator (HRSG)

Heat Recovery Steam Generator (HRSG)

Heat Recovery Steam Generator (HRSG)

Heat recovery steam generators are equipments which are used to extract heat from process gas or a waste gas streams and use that heat to convert liquid water into steam in order to use that steam in some other process or the HSRG is made part of a power generation unit where it uses the heat from the exhaust gases of turbines to convert liquid water into steam for use in the same power cycle. HRSG is basically a heat exchanger which has very high efficiency.

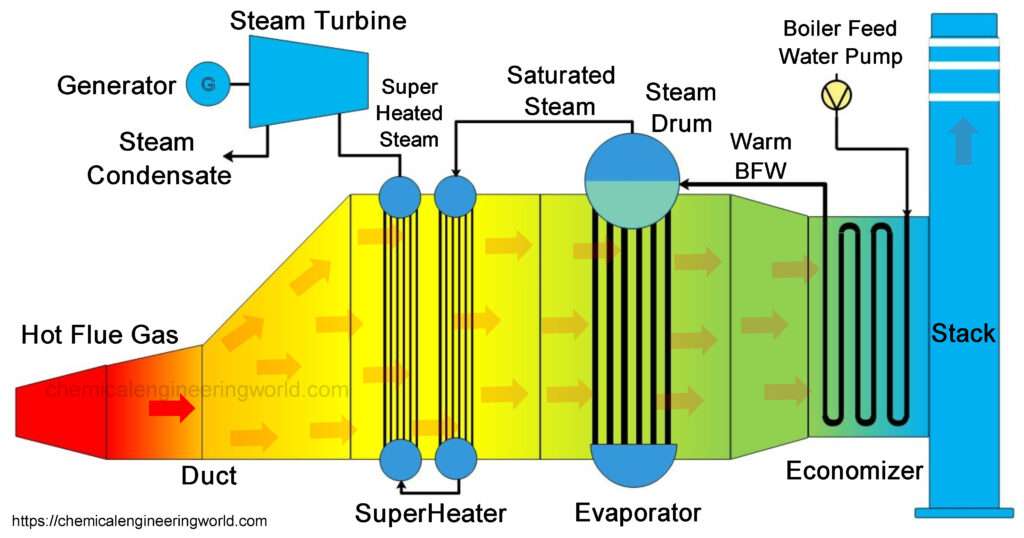

A HRSG system is made up of three major components; the economizer, the evaporator and the superheater. These components are arranged accordingly on order to get a highly efficient thermal exchange system. In some applications, a selective catalyst reduction (SCR) unit is installed with the HRSG in order to reduce the nitrogen content oxide in the exhaust gases of HRSG.

Working of HRSG

HSRG is essentially a large structure of network of pipes. The water is made to flow through the pipes and the hot gases are made to contact the pipes from the other side. The water and the hot gases are separated by the solid boundaries of the pipe material. The pipes are provided with extended fins in order to increase the effective heat transfer area.

The water is first passed through the economizer from where it passes through evaporator and then to superheater. The hot gases first come in contact with the superheater and then with evaporator and then with economizer. The temperature of the superheater section is highest in the system because it is the closest to the input of hot gases. The temperature of the economizer is the lowest among the three major components because it is farthest from the hot gases input.

The liquid water is fed in to the economizer, the function of economizer is to preheat the liquid before it passes to the evaporator section. The preheated liquid water then passes to the evaporator tubes where enough heat exchange occurs for the liquid water to get converted into steam. The steam may be saturated in nature hence it is passed to the superheater section where the temperature of steam increases so much that it becomes a superheated steam from a saturated steam. This superheated steam is then output from the HRSG system and then passed down the line to the next equipment in the process wherever it is required.

Selective Catalyst Reduction (SCR)

The HRSG has one more outlet which corresponds to the hot gas input. The gases cool down to a certain extent before exiting the system. If the HRSG is being used in a power cycle then the hot gases are the exhaust of the turbine. They contain nitrogen oxides which need to be neutralized before leaving the gas to disperse in atmosphere.

The nitrogen oxide gases are considered pollutants and global warming gases, they can cause irritation and inflammation of they are present in high quantities in the airways. They are responsible for formation of ground level ozone and also they react to form smog and acid rain.

A unit called selective catalyst reduction (SCR) is installed in applications which contain nitrogen oxides as one of the components. The SCR unit contains ammonia which are used to react with and neutralize the nitrogen oxides. After the hot gases serve their purpose of exchanging heat and converting water to steam, they are mixed with sufficient ammonia in order to follow the safety norms before releasing the gases to the atmosphere.

Classification of HRSG

They are classified based on the direction of flow of exhaust gases and the number of pressure levels involved.

- Based on direction of exhaust gases: they are classified into horizontal and vertical type. In horizontal type, the gases flow horizontally over vertical tubes. In vertical type, the gases flow vertically over the horizontal tubes.

- Based on the number of pressure level: they are classified as single pressure and multi pressure. In single pressure system the steam is generated in a single steam drum at one pressure level. In multi pressure systems the steam is generated in multiple steam drum, each drum operating at a different pressure level ranging from low pressure to high pressure.