Types of Flanges

Types of Flanges

Types of Flanges

- Welded neck flange

- Slip on flange

- Screwed flange

- Lap joint flange

- Blind flange

1. Welded neck flange: –

It is used for high temperature, high pressure operation or where there is wide fluctuation in pressure and temperature. These flanges are useful for handling costly, hazardous, flammable, explosive fluids, because failure or leakage of a flange joint can prove disastrous for the plant. The various dimensions to be specified for a welded neck flange are:

- (a) Outside diameter of flange.

- (B) Minimum flange thickness.

- (c) Outside diameter of raised face.

- (D) Diameter of hub at base.

- (E) Diameter of hub at point of welding.

- (F) Length through hub.

- (G) Diameter of hole.

- (H) Diameter of bolts.

- (I) Bolt circle diameter.

- (J) No. of holes.

2. Slip on flange: –

It is widely used because of ease of alignment in welding. Its cost is also less. The flange is useful for moderate service process operations where temperature, pressure changes, vibrations, shocks are not severe. Its strength is around 70% as that of the welded neck flange and its fatigue life is nearly 1/3 as compared to a welded neck flange

3. Screwed flange: –

Screwed flange can be connected to threaded pipes without welding. It is not useful for operations which involve bending or thermal cycles, because there is always possibility of leakage through the threaded joint. It can be used with high alloy steel for high pressure operations satisfactorily because welding of high alloy steel is difficult.

4. Lap joint flange: –

Lap joint flange is usually used with a lap-joint & hub. These are useful where temperature, pressure changes, vibrations and shocks are not severe. These flanges are not useful where severe bending stresses exist. These flanges have only about 10% of the fatigue life as compared to welded neck flange. For these flanges bolt holes can be easily aligned and this simplifies the installation of large diameter vessels. These flanges are useful for operations where the vessel is frequently opened up for cleaning and inspection.

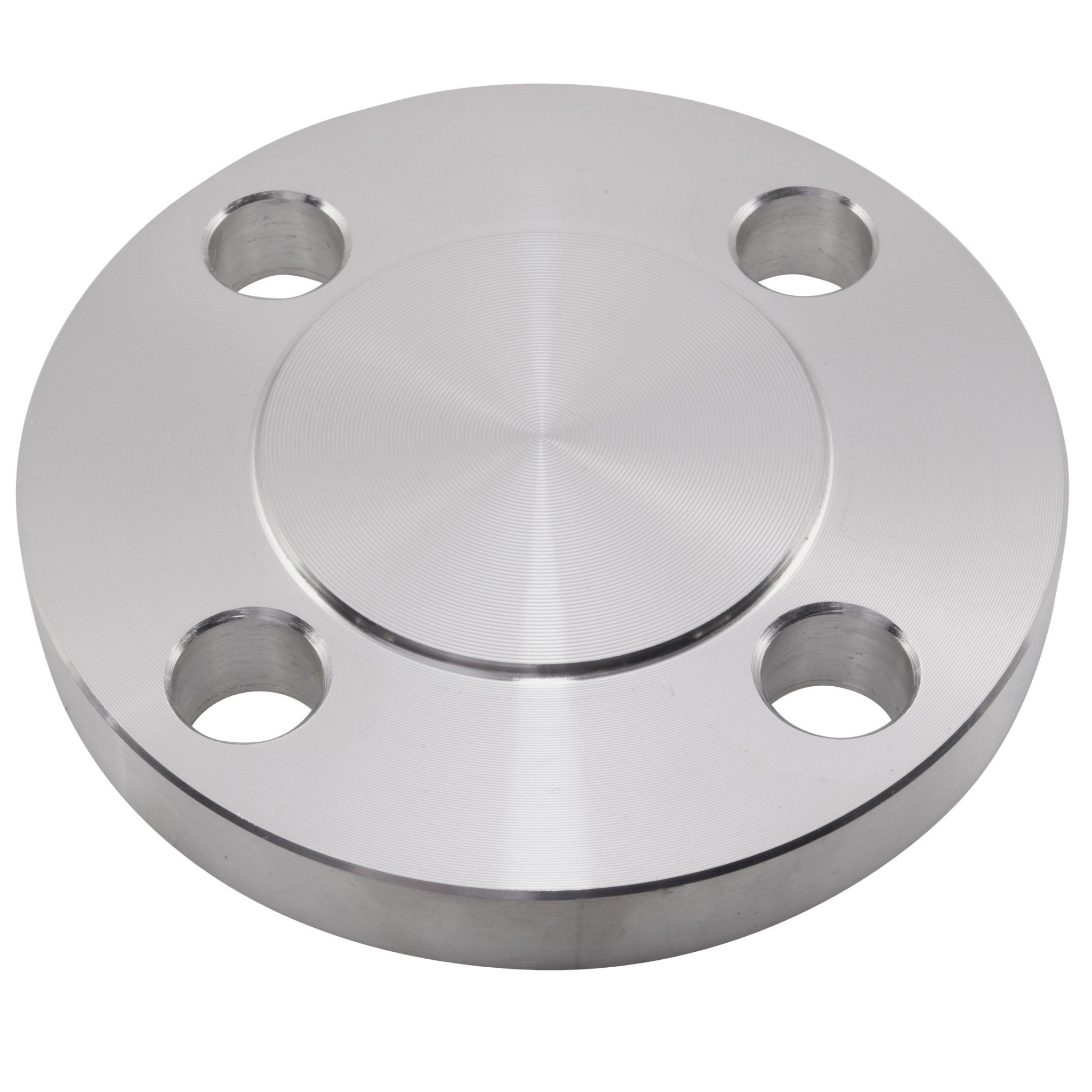

5. Blind flanges: –

Blind flanges are very commonly used for the pressure vessel openings e.g. hand holes and inspection parts. These are also used at the ends of pipes and valves. These flanges are capable of handling high bending stresses but do not have to absorb stresses due to thermal expansion. These flanges are used for heat exchangers. Blind flange is a flat plate. It is simply supported at the gasket load reaction line. It is loaded by a gasket seating load and a combination of gasket seating load, and uniform pressure load.

Reference wiki